SK Gas builds hydrogen production plant in Ulsan, investment amounts to several billion US dollars

South Korea’s third-largest conglomerate, SK Group, has named its subsidiary SK Gas Co. as the lead company for expanding its hydrogen business. In addition to building plants to produce green hydrogen, it will also develop fuel cells and batteries. According to multiple industry sources, SK Gas is investing several billion U.S. dollars to build a hydrogen production plant and related infrastructure along the southern coast of the Korean city of Ulsan by 2025. The company plans to build facilities and equipment for the entire hydrogen industry value chain. The project generates increased import demand for numerous, industry-relevant products that require KC certification for the Korean market. The plans include importing raw materials, production, storage and distribution. The mammoth project will cost SK Gas several billion U.S. dollars and moves its current main business in natural gas and liquefied petroleum gas significantly in the direction of hydrogen.

South Korea is pinning its hopes largely on hydrogen and its importance to industry, the economy and society as an environmentally friendly energy source and the country’s primary energy, as opposed to nuclear energy and fossil fuels. The government-initiated push for energy transition reached almost all well-known companies in this field such as SK, Hanwha and GS. Industry experts expect SK Gas to build up its hydrogen business from by-products of the chemical industry, at least in the beginning, in order to save costs in investment and production. Only later will the hydrogen also be produced with the help of renewable energy and have a good environmental balance.

SK Advanced, also based in Ulsan, is capable of producing around 30,000 tons of hydrogen annually as a byproduct. SK Gas, South Korea’s largest producer of liquefied natural gas, is also planning a plant to separate hydrogen from natural gas. By reusing and storing the resulting CO₂, the hydrogen can at least be called “blue hydrogen.” The hydrogen produced by SK Gas will be transported via pipelines up to 100 kilometers long to gas generators and fuel cells in other facilities in the Ulsan area.

To distribute the hydrogen, SK Gas is building a hydrogen liquefaction plant that will draw its cooling energy from the natural gas terminal. Through a joint venture with Lotte Chemical, the hydrogen will be sold at gas pumps. To this end, SK Gas plans to build around 100 hydrogen filling stations in South Korea by 2030. It has also entered into a joint venture with Lotte Chemicals to build a fuel cell power plant. A demonstration plant for a hybrid gas turbine powered by hydrogen is to be developed with Korea East-West Power and Doosan Heavy Industries. SK Gas has also established a venture capital company in Silicon Valley to invest in promising start-ups.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

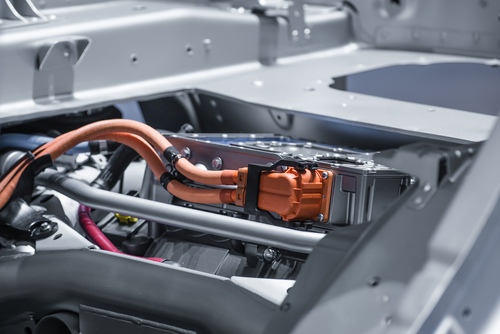

Hyundai and Kia report 42 percent increase in sales of their eco-friendly car models

Hyundai Motor Co. and Kia Corp. report a 42 percent year-on-year increase in sales of environmentally friendly new cars in their home country of South Korea. Environmentally friendly or green vehicles include electric-drive cars, hybrid vehicles and hydrogen-powered fuel cell vehicles. The two companies sold a total of 75,336 green vehicles in the period from January to May 2021. Of these, 54,560 were hybrid vehicles, 17,111 were e-cars and 3,665 were hydrogen vehicles. The year-on-year sales figures improved by 35.6; 62.2 and 59.7 percent, respectively. As a result, the market for hybrid vehicles is growing, which also means positive prospects for the Korean automotive industry. Growing production figures also mean increased imports and demand for various automotive parts and components, many of which are subject to mandatory KC certification.

Automotive industry observers made a connection between the increase in eco-car sales and the availability of chips and semiconductors. A senior executive said hybrid and e-cars require more semiconductors than conventional internal combustion vehicles. As a result, a shortage of semiconductors and electronic components recently led to frequent production stoppages and declines in hybrid car sales at Hyundai Motor again. In May, these surprisingly fell 24.8 percent year-on-year to 4,095 vehicles. As soon as the situation on the chip and semiconductor market improves again, experts expect a further rapid increase in car sales figures.

Is your company active in the automotive industry and has business relations with South Korea or plans to do so? Many products that are imported into South Korea have to be tested and certified in advance. MPR International GmbH recommends itself as a partner for your Korea certification. We gladly check for you without obligation whether your products are subject to certification and prepare an attractive offer for you.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Korean companies venture into wind energy market

Several Korean companies are entering wind power generation to take advantage of this global growth trend. POSCO Group plans to collaborate with Denmark’s Orsted, the world’s largest offshore wind energy producer. Orsted wants to build a 1.6 GW offshore wind power plant in Incheon, South Korea. POSCO Group is the local partner for this project. The project cost is expected to be $6.9 billion, with completion scheduled for 2026. Wind turbines are complex plants where numerous technical components and parts require KC certification (Korea Certification) to be imported, built and operated in Korea.

Hanwha Solutions is planning to build a plant to generate green hydrogen from wind energy in Gangwon Province. Subsidiary company Hanwha Q CELLS, responsible for the renewable energy business, is also expanding its wind energy resources and plans to participate in a 40 MW wind farm, also in Gangwon Province. In this, Hanwha Q CELLS is acting as an engineering and construction company. Another company, Hyosung Heavy Industries has formed a joint venture with China’s Goldwind and is planning an 8 MW wind farm.

Hyundai Heavy Industries is participating in the construction of a demonstration plant for the production of green hydrogen from offshore wind turbines. The plant’s capacity is expected to be 100 MW, with commissioning targeted for 2025. The company is developing a large-scale plant for the production of hydrogen from seawater and electricity from wind power at the Ulsan Floating Wind Farm. In a second phase of the project, another green hydrogen plant with 1.2 GW capacity will be built, in which Hyundai Heavy Industries is also involved. This is scheduled to begin operation in 2030.

In addition to hydrogen and wind power generation, Korean shipbuilders are also benefiting from the growth of offshore wind. As part of this, Samsung Heavy Industries (SHI) has developed a vessel for wind turbine installation that is based on environmentally friendly propulsion technology. SHI announced on May 8 that its SLW-FUEL CELL ship model concept has been classified as environmentally friendly in terms of low CO2 emissions by the world’s three leading ship classification organizations, ABS (USA), DNV (Norway) and LR (UK).

South Korea is considered one of the most important and innovative industrial nations in the world. In order to gain market access to this highly technological country, products imported into South Korea must be tested and certified. The KC mark or KC certificate is roughly equivalent to the European CE mark and applies to 730 different products. MPR International GmbH has solid experience in Korea certification and competent local partners. We gladly advise you without obligation about the scope and procedure of a Korea certification.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

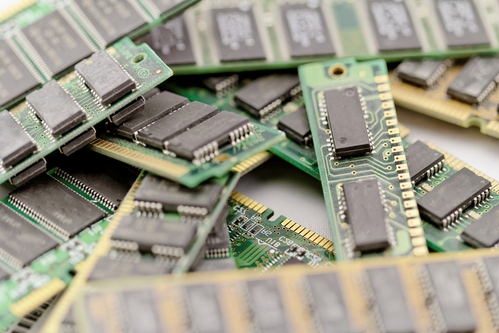

Memory chip makers expect supercycle until 2023

A so-called supercycle for global memory chip availability, combining price increases and supply shortages, will continue through 2023. As a result, the world’s largest memory chip makers, Samsung Electronics and SK hynix, expect record profits over the next two years. In their latest report, market watchers IC Insights expect global memory chip sales to rise 23 percent this year to $155.2 billion. Next year, the analysts expect a 16 percent increase to $180.4 billion, with a further 23 percent growth forecast for 2023 to a total of $219.6 billion. Memory chips, like many other electronic components, are among the products that potentially need to be KC certified in order to be imported and distributed in Korea.

The previous highs for memory chip sales of $163.3 billion came in 2018, when there was already a so-called memory supercycle. At that time, companies benefited from rising prices due to higher demand. A year later, however, the market collapsed with a 32 percent decline to $110.4 billion, ushering in a downward trend.

This year, due to rising demand from IT products, expansion of cloud data centers and the rapidly recovering global economy, demand for DRAM memory and flash memory has skyrocketed, drawing global supply concerns. According to IC Insights, DRAM memory accounts for 56 percent of the total memory market, while flash memory is at 41 percent. Due to the high global demand, analysts upgraded the profit forecasts of Korean chip giants Samsung Electronics and SK hynix for this year.

Samsung is the world’s largest DRAM chipmaker with 42 percent market share, followed by SK hynix with 29 percent. Samsung is also number one in flash memory chips, with 32 percent market share. SK Hynix, whose market share for flash memory was 9.9 percent in 2019, could move to second place after the completed purchase of Intel’s flash memory division and have about 20 percent market share.

South Korea is considered one of the most important and innovative industrialized nations in the world. Many products imported to South Korea have to be tested and certified in advance. MPR International GmbH recommends itself as a partner for your Korea certification. We gladly check for you without obligation if your products are subject to certification and create an attractive offer for you.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.