Imports of luxury vehicles increase 74 percent year-on-year

As the market share of imported cars continues to expand, demand for luxury vehicles with a price tag equivalent to more than $85,000 increased last year. Of imported cars in this price range, 39,965 were sold in the first seven months of the current year. This represents 23.2 percent of the total 172,146 vehicles imported into South Korea during the period. The data was provided by the Korean Association of Auto Importers and Distributors. The Korean automotive market is strong; growth is recovering in manufacture and production since the beginning of the COVID-19 crisis. International supply lines are active and import of components, which often need KC certification, is closing in on levels comparable to 2019.

The business of imported luxury vehicles priced at $85,000 or higher grew 74 percent year-on-year. Their share within total imported vehicles rose 8 percent to 15.5 percent. Sales of expensive imported vehicles from three German automakers, Mercedes-Benz, BMW and Audi, doubled from last year. Mercedes-Benz continues to rank first with 17,524 vehicles, followed by BMW with 5,286 vehicles and Audi with 2,437 vehicles.

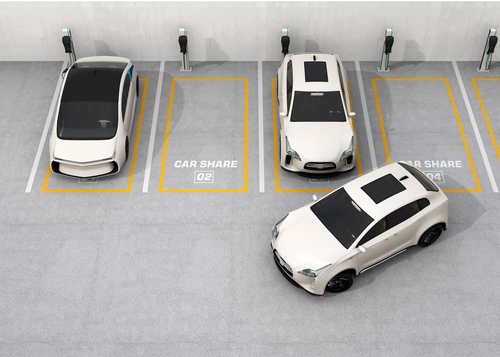

SUVs and cars with environmentally friendly engines are enjoying increasing popularity in the category of expensive imported vehicles. Sales of SUVs more than doubled to 21,398 units. Imported vehicles with environmentally friendly engines (hybrid, plug-in and electric) were in very high demand. Sales of these increased fourfold year-on-year to 20,470 units. Sales of these vehicles now outstrip imported luxury cars with conventional gasoline or diesel engines. Their share of imports to Korea now accounts for 51.2 percent, up from just 22.2 percent in 2020.

Is your company in the automotive industry and has or plans to have business relations with South Korea? Many products imported into South Korea must be pre-tested and certified. MPR International GmbH recommends itself as a partner for your Korea certification. We gladly check for you without obligation whether your products are subject to certification and prepare an attractive offer for you.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Korea’s LG Display invests $3 billion to double its OLED manufacturing capacity

LG Display Co. plans to invest around $3 billion to double its manufacturing capacity for small and mid-sized OLED displays. The manufacturer is now looking to extend its global leadership in TV displays to other devices with smaller screens. LG Display announced last Tuesday that its board of directors had approved the relevant investment to install a latest-generation OLED display production line at LG’s Paju factory in Gyeonggi Province. As a result, the need for imported components and equipment is also expected to increase, in many cases requiring KC certifications or KCs certifications for machinery. Commissioning is scheduled for 2024.

The new production line will double the capacity for small and medium-sized OLED displays to about 60,000 units per month. According to informed industry sources, LG will also supply OLED displays for Apple’s next-generation iPads and iPhones. For some time now, LG Display has been trying to expand its business to smaller diagonals in addition to large TV screens. While LG Display is the global market leader for OLED TV displays, Samsung Display dominates the market for smaller devices.

Last year, LG Display shipped around 25 million OLED screens for mobile devices, including Apple’s iPhone 12. However, Samsung Display remains the clear market leader in this segment with 82.1 percent market share, while LG Display is a distant second with 7.5 percent. In recent years, smartphones have increasingly been equipped with the high-quality OLED screens. According to analyses by the market researchers at Omdia, the volumes shipped will increase from the current 564 million to 773 million units by 2025. LG Display’s largest customer in the smartphone sector, Apple, has been equipping its iPhone and iPad models with OLED screens since 2017. LG Display now anticipates that other manufacturers will follow this example and also deliver their devices with OLED screens as standard.

South Korea is considered one of the most important and innovative industrial nations in the world. Many products that are imported into South Korea have to be tested and certified in advance. MPR International GmbH recommends itself as a partner for your Korea certification. We gladly check for you without obligation if your products are subject to certification and create an attractive offer for you.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Korea introduces special laws for battery and chip industry

The government reiterated its support for the domestic battery industry and related industries to develop them into a global export hit, similar to semiconductors and computer chips. New technologies are to be developed, small and medium-sized companies are to be helped, and opportunities for education and training are to be created. To discuss the details of the plan, the minister of trade, industry and energy met with representatives of local battery manufacturers at Samsung SDI’s factory in the southeastern industrial city of Ulsan. At the meeting, Moon said the administration would work to introduce special laws to support key industries such as battery manufacturing and semiconductors to stabilize supply chains and ensure future competitiveness. Growing production depends on strong supply chains needed to import KC-certified parts and components and export to foreign markets.

Moon made clear at the meeting that South Korea would continue to pursue the development of battery technology, attracting well-known companies and training skilled workers. Participants in the small summit included representatives from Samsung SDI, EcoPro BM, Chunbo, Isu Chemical, Iljin Materials and Dong-Il Aluminum. Samsung SDI is one of the country’s top three battery manufacturers, producing a wide variety of batteries for electric cars, energy storage, smartphones, electric scooters and tools. As an offshoot of the Samsung Group, the company is also a leader in research and development of new technologies.

As a result of the talks, the government will soon announce the key points of a so-called “K-Battery” strategy. The country already adopted a “K-Semiconductor” plan in May this year. In cooperation with Samsung Electronics and SK Hynix, the goal is to create the world’s largest industrial and supplier location by 2030. LG Energy Solutions (LGES), Samsung SDI and SK Innovation (SKI) will announce their investment plans regarding the expansion of their capacities for battery products in the coming months. The government promises aid measures for the recruitment of qualified workers and tax breaks for this purpose.

South Korea is considered one of the most important and innovative industrial nations in the world. Many products imported into South Korea have to be tested and certified in advance. MPR International GmbH recommends itself as a partner for your Korea certification. We gladly check for you without obligation if your products are subject to certification and create an attractive offer for you.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

New Regulations for wireless EV charging service approved

Hyundai Motor has planned a remote charging system for battery-powered electric vehicles and has achieved approval by the Korean government, as announced this week.

The government aims to boost new business opportunities and technologies by changing regulations that may hamper incentives for innovation. Hyundai Motor’s project entails cordless charging of electric cars. The concept involves receivers installed on the vehicles and at electric charging stations. Such a vision was previously impossible due to missing laws which would grant the use of frequency bands for car charging processes. The approval of the project is supposed to enable further expansion of electric vehicles and improve customer convenience, according to the ministry.

Experts hope for a further increase in EV distribution numbers on the Korean market, which has already established itself as one of the strongest expanding markets worldwide. Production has recovered strongly after the covid crisis, with increasing demands in production resources and technical components. Korean EV carmaking continues to be dependent on import of industry related products through international supply lines, which in turn requires KC, KC EMC, KCs and other Korea certification processes to ensure conformity of the products with Korean safety and quality regulations.

With this development Hyundai Motor is on its way to become the first Korean carmaker using wireless charging technology for its EVs. Testing is supposed to start by the fourth quarter this year to collect data to prepare for related infrastructure. These plans also include wireless charging for e-scooters, enabling remote charging.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

KOGAS begins production of liquid hydrogen using cold energy from its liquefied natural gas plant

Korea Gas Corp. (KOGAS) will soon begin producing liquid hydrogen using released cooling energy from its liquefied natural gas plant. KOGAS announced on May 30 that it has entered into a strategic partnership with GS Caltex regarding the production and distribution of liquid hydrogen. The two companies plan to build a large-scale hydrogen liquefaction plant with an annual capacity of 10,000 tons. The hydrogen produced will initially be sold in the Seoul metropolitan area, and later in the central region of South Korea. Major projects in this area mean increased use and production of industrially relevant parts, components and equipment, of which most must undergo KC certification or KCs certification for explosion-proof products for the Korean market.

The project will split hydrogen from natural gas and convert it into liquid hydrogen. The cooling energy required for this will come from the company’s own liquefied gas plant. The liquid hydrogen will then be transferred to tank trucks and delivered to filling stations. The plant is scheduled for completion in December 2024. Liquid hydrogen is easier to store and transport than in gas form, as its volume is reduced by a factor of 0.00125.

Production at KOGAS has the advantage of saving around 30 percent of costs due to the otherwise unused cooling energy of the liquid natural gas plant. The process at KOGAS of using the cooling energy from liquid natural gas to produce liquid hydrogen is unique in the world. The cooling energy is generated when the aggregate state of the delivered liquefied gas changes to gas form. This produces around 200 Kcal of cooling energy per kilogram. Previously, this energy was lost to the ambient air or seawater. Its recent use as an environmentally friendly energy source respectively cooling energy has attracted the attention of numerous companies to this process.

South Korea is considered one of the most important and innovative industrial nations in the world. In order to gain market access to this highly technological country, products imported into South Korea must be tested and certified. The KC mark or KC certificate is roughly equivalent to the European CE mark and applies to 730 different products. MPR International GmbH has solid experience in Korea certification and competent local partners. We gladly advise you without obligation about the scope and procedure of a Korea certification.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.