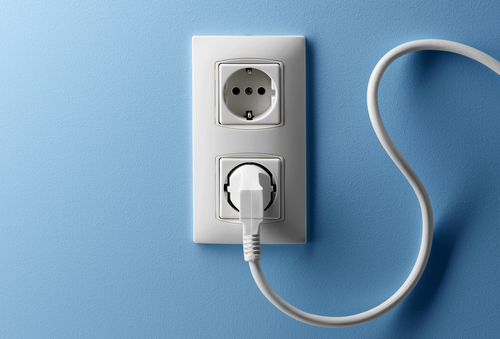

South Korean machinery maker SFA, previously active in manufacturing machinery for the display screen industry, plans to expand its business to include semiconductors, batteries and logistics. This is necessary to give the company a broader base, CEO Kim Young-min told The Korea Times newspaper. He expects SFA to increase orders from the battery and logistics sectors as early as this year. Kim went on to say that his company aims to become the market leader in “smart factory equipment” in the long run. Many industry experts believe this sector promises high growth potential as digital technologies such as artificial intelligence (AI) and Big Data analytics help companies make better products more cheaply. In addition, SFA aims to actively target overseas markets and customers with its smart factory solutions and become a global market leader, Kim said. Products in these categories generally require

KC Safety certification for electronic products in order to be approved for the Korean market.

SFA was founded in 1998 and has since specialized in the design and manufacture of automated machinery and systems for the display industry. However, board member Kim recognized the need for his company to diversify to be less dependent on the volatile display industry. SFA’s transformation began as early as 2017 and could show initial success in 2021, Kim said. Most promising, he said, are automated equipment for the production of EV batteries. These will continue to account for the largest share of new business at SFA, according to Kim. SFA’s machines can be used in automatic safety testing and quality control of automotive batteries, among other applications. For the current year, SFA has already received an order from a major Korean battery manufacturer, and more orders from other companies are on the horizon for the second half of the year, Kim said. To expand its position in the market, SFA is developing equipment for assembling battery packs from individual cells, as used in the automotive industry or battery manufacturing, in addition to inspection machines.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different authorities and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best contact for competent service when it comes to exporting to Korea. For example,

KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like

KC for electronic products,

KC EMC,

KCs,

KCs for explosion safety products or

KGS factory registration.

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

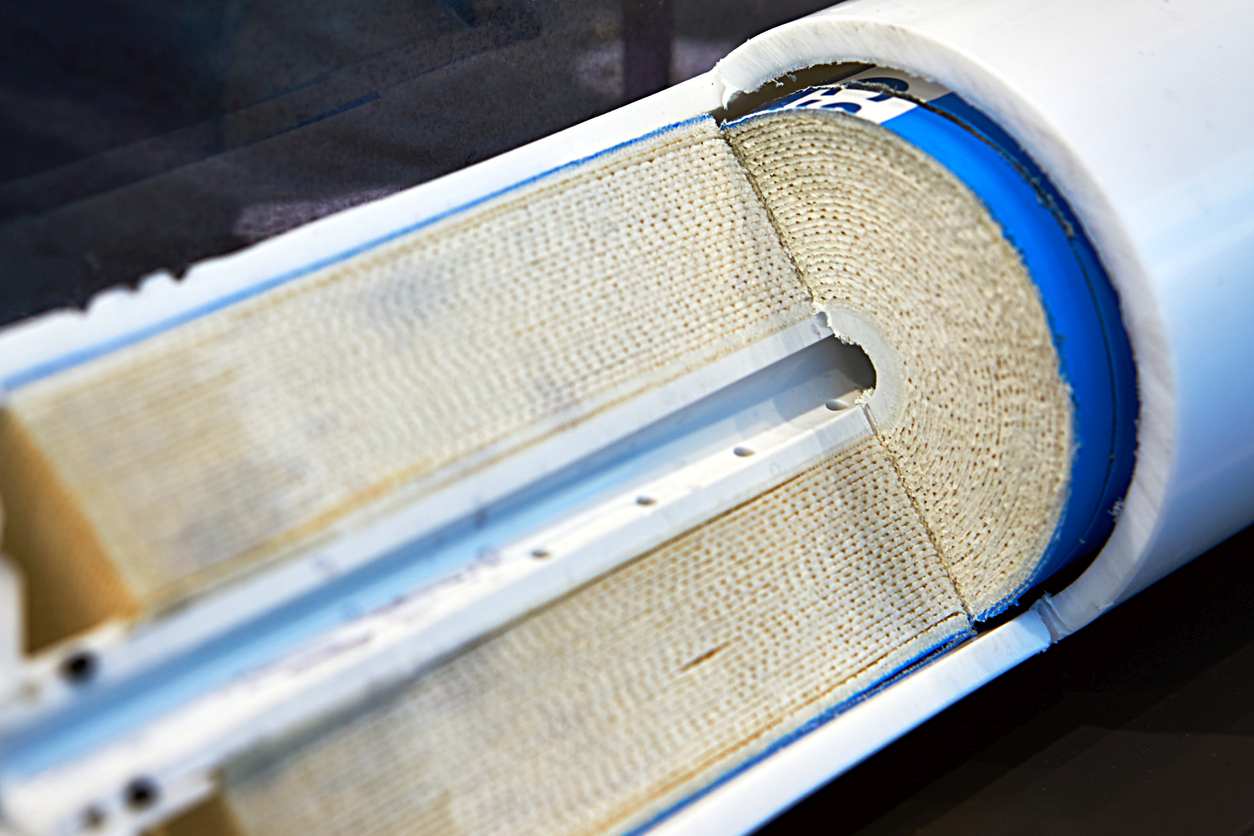

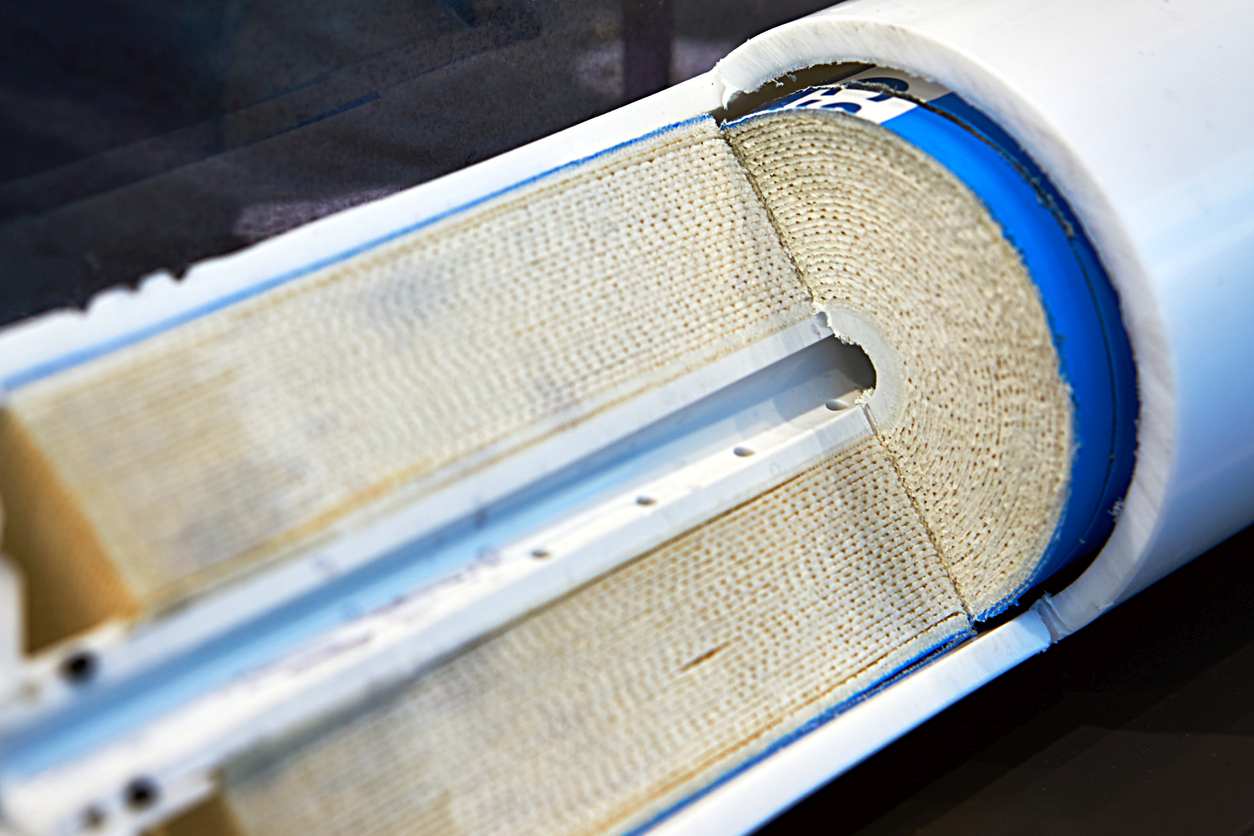

South Korean company Coway, a specialist in water and air filters, recently unveiled the second generation of its Icon Water Purifier water filter. Consumers in South Korea are becoming more discerning in their choice of water filters, which have become major household appliances in recent years, according to media reports. In general, devices with appealing designs and small footprints are the most popular. Customers are also concerned about the cleanliness inside the devices in the wake of increasing pollution and COVID-19. Therefore, it is important to choose a manufacturer whose water filter regularly checks the filter quality and suggests changing the filter. Water filters, air filters and similar products for household use often require

KC Safety certification to ensure the safety and quality of the product, qualifying it for the Korean market.

Coway took all these influences as an opportunity to develop the Icon Water Purifier 2. This has a modern design and novel purification functions. For example, every six hours, the device performs a 15-minute sterilization of the tap with UV light. In addition, the water filter notifies the owner when a filter needs to be changed. Most of the components are made of Tritan, a special plastic from Eastman Chemical that prevents microorganisms from settling. The special design of the cartridges allows the user to easily remove and clean them. The Icon Water Purifier 2 water filter also passed a materials test conducted by the U.S. Food and Drug Administration (FDA).

Compared to Coway’s first-generation Icon water filter, the latest version features an improved filtration system, hot water temperature control and pressure regulator. A 7-inch nano trap filter that has been increased in size by one inch over the previous model. The nano-filter is capable of filtering out a total of 94 harmful substances from tap water, including viruses, plasticizers and algae toxins.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different agencies and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best resource for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like

KC,

KC EMC,

KC Safety certification,

KCs for explosion safety products or

KGS factory registration.

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

Specifically, the two divisions are the chemicals and recycling divisions of SK, South Korea’s second-largest conglomerate. As reported by Pulsenews, the collaboration with new global partners is expected to improve SK Group’s CO₂ balance and become a top player in South Korea and abroad in the future. SK Chemicals signed a memorandum of understanding with China’s Shuye Environmental Technoloy, aiming to establish a joint venture. SK Chemicals is to hold 51 percent of the shares in the joint venture. Last May, SK Chemicals already acquired a ten percent stake in Shuye worth around 17 million US dollars. In return, the Chinese company will supply SK with 20,000 metric tons of chemical recycling material annually. The newly formed joint venture is building a depolymerization plant with a capacity of 100,000 tons of raw material and another plant to produce 200,000 tons of recycled polyethylene (CR-PET) and co-polyester under the management of SK Chemicals. The two plants are scheduled to start operations at the end of 2024. SK Chemicals introduced two new environmentally friendly plastics last year: co-polyester Ectotria CR and chemically recycled PET called Skypet CR. Machinery and equipment to carry out these projects usually falls and

KCs certification and under

KC-EMC testing regulations to be allowed to be imported and used in Korea.

Another SK Group company, SK geo centric, will cooperate with the French company Veolia in the future. A memorandum of understanding was also signed for this purpose, which involves expanding plastics recycling in Asia. To this end, both companies are researching processes for the pyrolysis of PET, PP and plastic waste, as well as an expansion of SK’s geo centric recycling center in Ulsan, South Korea. SK geo centric President and CEO Na Kyung-soo said he was pleased with the cooperation with Veolia: “This is the start of a circular economy in the Asian market and shows the competencies of both companies in the field of environmentally friendly solutions. SK geo centric plans to become the circular economy market leader in Asia with its plastic waste recycling plant in Ulsan, Kyung-soo added.

KCs certification was introduced in South Korea to ensure basic safety in the design and manufacture of hazardous machinery and protective equipment in hazardous workplaces in Korea. The goal is to protect the health and safety of workers by preventing accidents. We provide certification services for all product areas, including KC certification for consumer products and especially electronics,

KC-EMC certification for electronic products, and KCs certification for machinery, as well as

KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance.

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

South Korea, the United States and 16 other countries established a working alliance in May to accelerate cooperation in the development of the hydrogen industry, an industry ministry spokesman said. Member countries of the Global Hydrogen Industrial Association Alliance reported on the current status of their hydrogen industries and planned policies at the founding event in Seoul. Led by South Korea, the alliance plans to establish a network for contacts and a hub for hydrogen data and information. According to the Ministry of Trade, Industry and Energy, this should help develop the technology and reduce regulatory restrictions. Participating countries at the first meeting included China, the United Kingdom, Germany and Singapore. Pressure vessels and similar product categories associated with the production of hydrogen require approval through the

Korea Gas Safety Corporation (KGS) to be distributed and used in Korea.

Deputy Industry Minister Park Il-jun promoted building large-scale hydrogen production plants in South Korea, as well as facilities for transport and storage both domestically and abroad. This is expected to create a complete system from production through distribution and use of the gas. South Korea’s efforts stem from its shift in energy production from nuclear power and coal to clean and sustainable energy sources. Hydrogen is an environmentally friendly alternative to fossil fuels because it releases only water during the combustion process. Hydrogen gas is produced as a byproduct in industry and petrochemical plants, among others.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like

KC,

KC EMC,

KCs,

KCs for explosion safety products or

KGS factory registration.

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

South Korean company Hyundai Engineering is stepping up its activities in micro-reactors (SMR) and hydrogen generation. As a result, Hyundai hopes to lead the way in energy security and CO₂ emissions reduction. According to its strategic roadmap for nuclear reactors and engineering services in the energy sector, the company aims to expand its business to include small and micro modular reactors (SMR and MMR, respectively), hydrogen production, nuclear power plant decommissioning, and fissile material fuel production for nuclear power plants. Based on its capabilities in power plant design and manufacturing, Hyundai aims to become a major competitor in the modular reactor field. Pressure vessels and similar product categories associated with the production of hydrogen require approval through the

Korea Gas Safety Corporation (KGS) to be distributed and used in Korea.

Hyundai Engineering plans to secure rights to engineer, procure and construct microreactors in Canada, the U.S. and Poland by 2029. In doing so, the company is applying its experience from the MMR project in Chalk River, Canada. It is also working on technical improvements for the production of hydrogen in large quantities under a high-temperature process. Regarding nuclear power plant decommissioning and fuel rod disposal, Hyundai plans to participate in the design of interim storage facilities for the disposal of nuclear waste from the microreactors. In addition, the strategy calls for securing additional rights overseas for pyrolysis and treatment of radioactive waste. According to the company, it is prepared for the decommissioning and dismantling of nuclear power plants in South Korea. Based on Hyundai’s experience with the OYSTER research reactor in the Netherlands, the company hopes to gain further participation in similar projects in South Africa and Bangladesh.

We provide certification services for all product areas, including KC certification for consumer products and especially electronics, KC EMC certification for electronic products, and KCs certification for machinery, as well as KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like

KC,

KCs,

KCs for explosion safety products or

KGS factory registration.

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

Samsung Electronics, LG Electronics, SK Telecom, KT, Kia and other well-known companies from South Korea were among the exhibitors at the World IT Show in April 2022. The largest IT event in the capital city of Seoul, hosted by the Ministry of Information and Communications Technology (ICT), offers companies the opportunity to showcase their latest trends and future products. This year’s exhibition was themed “Transitioning the Global Community from Pandemic to Endemic.” Organizers reported that more than 350 large, small and medium-sized companies and public institutions participated in the exhibition. The show was divided into these areas: contactless technology, artificial intelligence (AI) and Internet of Things (IoT), digital worlds and metaverse, smart devices, digital healthcare, and cybersecurity and blockchain. Many electronic products need a

KC certification in order to be approved for the Korean market.

Among the well-known exhibitors was Samsung Electronics, the world’s number one in smartphones and TVs, showcasing its latest gadgets such as the Galaxy S22 series devices and the foldable Galaxy Z Flip 3. LG Electronics also showed robots and gadgets for business customers in addition to its home appliances. An LG spokesperson elaborated further on the exhibits: For example, the LG CLOi ServeBot assistance robot greeted guests at the LG booth and explained the products on display. In the Smart Office Solutions area, LG introduced the LG One:Quick, a 4K touchscreen with camera, microphone and speaker for hospitals and clinical facilities. South Korean mobile operator KT presented smart cleaning robots for quarantine facilities and hospitals, as well as monitoring and control systems for road traffic, as part of its restructuring as a digital platform provider.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different authorities and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best contact for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like

KC,

KC EMC,

KCs an more.

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

The South Korean company Lotte Chemical is investing the equivalent of 7.68 billion US dollars in the hydrogen and battery materials business areas by 2030. In addition, the turnover in these sectors is to increase to 38.42 billion US dollars, of which 9.22 billion US dollars are to be invested in environmentally friendly business sectors. These figures and business plans were announced at the “Lotte Chemical 2022 CEO IR day” in Seoul at the end of March. Compressed gases and similar products must undergo

KGS certification to be approved in Korea.

Lotte Chemical identified hydrogen, battery materials, recycling and bio-plastics as new growth drivers and therefore decided to invest about 8 billion US dollars until 2030. The largest part will be invested in hydrogen energy, followed by battery materials and, with a comparatively small amount, recycling and bio-plastics. For this purpose, the hydrogen energy and battery materials business units will be newly founded.

The Hydrogen Energy Division is to secure the leading role in the entire value chain. This includes, among other things, the production, transport and distribution of hydrogen as well as securing the necessary supply of ammonia, which serves as a feedstock for hydrogen production. To this end, mainly so-called blue and green ammonia is to be imported from overseas by 2030, which will then be converted into a total of 1.2 million tonnes of hydrogen gas in Korea. Lotte Chemical is also promoting the expansion of the hydrogen filling station network as well as energy production with hydrogen by participating in corresponding joint ventures.

In battery materials, Lotte Chemical expects sales of US$3.84 billion by 2030 and hopes to become a major player within the electric vehicle, battery and materials supply chain. To this end, Lotte Chemical, together with its subsidiaries Lotte Fine Chemical and Lotte Aluminium, is investing directly or indirectly in four key battery precursors.

We offer certification services for all product areas, including

KGS certification,

KC EMC certification for electronic products and

KCs certification for machinery, as well as

KCs for explosion-proof products. We are at your disposal for all questions regarding Korea certifications.

Feel free to contact us any time if you need assistance or have any questions:

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

TVs with OLED displays will account for about 40 percent of all premium sets sold this year, Pulsenews Korea reports. This makes the technology a standard for home flat-panel displays, reaching more than 20 million units shipped. The inventor of OLED displays, LG Electronics, is responsible for more than 60 percent of the shipments. According to market trackers Omnia in mid-May, a total of 20 million units have been sold since the introduction of OLEDs in 2013 through the end of March 2021. The speed at which OLED displays have conquered the market is remarkable. While the number of units shipped was still 10 million in September 2020, this figure has doubled in less than two years. Most electronic products and components must be awarded a

KC certificate in order for the products to be exported to China or manufactured locally.

Among manufacturers, LG Display dominates the OLED TV market and is capable of producing up to 7.42 million units annually. This increase only became possible with this year’s startup of a new factory in Guangzhou, China. Previously, the plant in Paju, South Korea, shipped about 4 million units annually. Rival Samsung Display, which makes OLEDs using its own QD (Quantum Dot) technology, is estimated to ship more than 10 million units this year. Pulsenews reports 21 manufacturers worldwide in the market for OLED displays or TV sets and therefore assumes a further spread of this technology.

KC certification for electronic products is a complex project that requires professional supervision at all stages. Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like

KC,

KC EMC,

KCs,

KCs for explosion safety products or

KGS factory registration.

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

Korean companies Samsung Electronics and LG Electronics are looking to launch more home appliances with functions for pet owners. This is in response to the growing number of pet owners, the companies’ respective spokespeople said in early May. LG Electronics, for example, is offering a software upgrade for certain home appliances with new programs specifically for pet owners. Owners of LG’s Tromm, Mini and Wash Tower series washers and dryers can use the new programs to better clean clothes of stubborn stains, dirt or grass. In addition to the software upgrade, LG dryers can also be equipped with a filter for pet hair. Machines used in households often need a

KC safety certification, in order to be approved for sale and use in Korea.

Samsung, in addition to washers and dryers, has also adapted vacuum cleaners and air filters specifically for pet owners. For example, the Cube Air air filter can remove pet hair and odors from the air. The brand’s robotic vacuum cleaners monitor pet behavior and send an alert to the owner in case of abnormalities. According to a spokesperson, Samsung plans to expand its products for customers with pets in the future.

KC safety certification was established to ensure basic safety in the design and manufacture of machines used in households in Korea. The goal is to protect the health and safety of consumers by preventing accidents. We provide certification services for all product areas, including KC certification for consumer products and especially electronics, KC-EMV certification for electronic products, and KCs certification for machinery, as well as KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like

KC,

KC EMC,

KCs,

KCs for explosion safety products or

KGS factory registration.

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

The “Special Act on the Safety of Children’s Products”, in short “Children’s Products Act”, is one of the most important South Korean regulations on the requirements for both locally manufactured and imported children’s products sold in the country. With the announcement of February 3, 2022, this law underwent some changes for the first time since 2016, which will take legal effect from August 4, 2022. Numerous products for children require

KC certification in Korea.

The revision mainly deals with non-compliant products, for whom penalty descriptions used to be rather vague. A focus lies on products that fall under the so-called Safety Confirmation (Type 2) in Korea. This category currently includes, e.g., baby clothing, sports equipment and bicycles for children, highchairs, skateboards, and toys.

Whenever manufacturers of KC certified products make incorrect statements when preparing test reports, untruthfully claim to be a “safety-friendly enterprise“, do not mark their products with the KC logo or apply the marking in a wrong way, the responsible Korean ministry may now demand rectification within six months (or less at its discretion) and suspend the existing certification of affected products for the corresponding period. Any marking of products with the KC logo is not permitted within this period.

In the case of intentional untruthful statements from manufacturers, testing and certification institutions will further be instructed to begin re-certification of the affected products after no less than a one-year suspension period.

An additional update faces the Korea Product Safety Management Agency, which will play a greater role in monitoring existing certifications in the future. It is to actively support the Ministry of Industry and Trade and the regional governments in the implementation of the relevant regulations. For this purpose, it may also impose the above-mentioned penalties on its own.

Children’s products, i.e., products intended primarily for babies and children up to the age of 12, are subject to strict regulations in Korea. Many products require a

KC certificate. Depending on the risk they pose to the age group, products fall into one of three certification categories, some of which require product tests or even a factory audit. Violations of the import and marking regulations are strictly punished by the authorities and may lead to fines or the loss of acquired certifications in the worst case.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like

KC,

KC EMC,

KCs,

KCs for explosion safety products or

KGS factory registration.

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

SFA was founded in 1998 and has since specialized in the design and manufacture of automated machinery and systems for the display industry. However, board member Kim recognized the need for his company to diversify to be less dependent on the volatile display industry. SFA’s transformation began as early as 2017 and could show initial success in 2021, Kim said. Most promising, he said, are automated equipment for the production of EV batteries. These will continue to account for the largest share of new business at SFA, according to Kim. SFA’s machines can be used in automatic safety testing and quality control of automotive batteries, among other applications. For the current year, SFA has already received an order from a major Korean battery manufacturer, and more orders from other companies are on the horizon for the second half of the year, Kim said. To expand its position in the market, SFA is developing equipment for assembling battery packs from individual cells, as used in the automotive industry or battery manufacturing, in addition to inspection machines.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different authorities and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best contact for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC for electronic products, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

SFA was founded in 1998 and has since specialized in the design and manufacture of automated machinery and systems for the display industry. However, board member Kim recognized the need for his company to diversify to be less dependent on the volatile display industry. SFA’s transformation began as early as 2017 and could show initial success in 2021, Kim said. Most promising, he said, are automated equipment for the production of EV batteries. These will continue to account for the largest share of new business at SFA, according to Kim. SFA’s machines can be used in automatic safety testing and quality control of automotive batteries, among other applications. For the current year, SFA has already received an order from a major Korean battery manufacturer, and more orders from other companies are on the horizon for the second half of the year, Kim said. To expand its position in the market, SFA is developing equipment for assembling battery packs from individual cells, as used in the automotive industry or battery manufacturing, in addition to inspection machines.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different authorities and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best contact for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC for electronic products, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Coway took all these influences as an opportunity to develop the Icon Water Purifier 2. This has a modern design and novel purification functions. For example, every six hours, the device performs a 15-minute sterilization of the tap with UV light. In addition, the water filter notifies the owner when a filter needs to be changed. Most of the components are made of Tritan, a special plastic from Eastman Chemical that prevents microorganisms from settling. The special design of the cartridges allows the user to easily remove and clean them. The Icon Water Purifier 2 water filter also passed a materials test conducted by the U.S. Food and Drug Administration (FDA).

Compared to Coway’s first-generation Icon water filter, the latest version features an improved filtration system, hot water temperature control and pressure regulator. A 7-inch nano trap filter that has been increased in size by one inch over the previous model. The nano-filter is capable of filtering out a total of 94 harmful substances from tap water, including viruses, plasticizers and algae toxins.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different agencies and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best resource for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KC Safety certification, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Coway took all these influences as an opportunity to develop the Icon Water Purifier 2. This has a modern design and novel purification functions. For example, every six hours, the device performs a 15-minute sterilization of the tap with UV light. In addition, the water filter notifies the owner when a filter needs to be changed. Most of the components are made of Tritan, a special plastic from Eastman Chemical that prevents microorganisms from settling. The special design of the cartridges allows the user to easily remove and clean them. The Icon Water Purifier 2 water filter also passed a materials test conducted by the U.S. Food and Drug Administration (FDA).

Compared to Coway’s first-generation Icon water filter, the latest version features an improved filtration system, hot water temperature control and pressure regulator. A 7-inch nano trap filter that has been increased in size by one inch over the previous model. The nano-filter is capable of filtering out a total of 94 harmful substances from tap water, including viruses, plasticizers and algae toxins.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different agencies and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best resource for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KC Safety certification, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Another SK Group company, SK geo centric, will cooperate with the French company Veolia in the future. A memorandum of understanding was also signed for this purpose, which involves expanding plastics recycling in Asia. To this end, both companies are researching processes for the pyrolysis of PET, PP and plastic waste, as well as an expansion of SK’s geo centric recycling center in Ulsan, South Korea. SK geo centric President and CEO Na Kyung-soo said he was pleased with the cooperation with Veolia: “This is the start of a circular economy in the Asian market and shows the competencies of both companies in the field of environmentally friendly solutions. SK geo centric plans to become the circular economy market leader in Asia with its plastic waste recycling plant in Ulsan, Kyung-soo added.

KCs certification was introduced in South Korea to ensure basic safety in the design and manufacture of hazardous machinery and protective equipment in hazardous workplaces in Korea. The goal is to protect the health and safety of workers by preventing accidents. We provide certification services for all product areas, including KC certification for consumer products and especially electronics, KC-EMC certification for electronic products, and KCs certification for machinery, as well as KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Another SK Group company, SK geo centric, will cooperate with the French company Veolia in the future. A memorandum of understanding was also signed for this purpose, which involves expanding plastics recycling in Asia. To this end, both companies are researching processes for the pyrolysis of PET, PP and plastic waste, as well as an expansion of SK’s geo centric recycling center in Ulsan, South Korea. SK geo centric President and CEO Na Kyung-soo said he was pleased with the cooperation with Veolia: “This is the start of a circular economy in the Asian market and shows the competencies of both companies in the field of environmentally friendly solutions. SK geo centric plans to become the circular economy market leader in Asia with its plastic waste recycling plant in Ulsan, Kyung-soo added.

KCs certification was introduced in South Korea to ensure basic safety in the design and manufacture of hazardous machinery and protective equipment in hazardous workplaces in Korea. The goal is to protect the health and safety of workers by preventing accidents. We provide certification services for all product areas, including KC certification for consumer products and especially electronics, KC-EMC certification for electronic products, and KCs certification for machinery, as well as KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Deputy Industry Minister Park Il-jun promoted building large-scale hydrogen production plants in South Korea, as well as facilities for transport and storage both domestically and abroad. This is expected to create a complete system from production through distribution and use of the gas. South Korea’s efforts stem from its shift in energy production from nuclear power and coal to clean and sustainable energy sources. Hydrogen is an environmentally friendly alternative to fossil fuels because it releases only water during the combustion process. Hydrogen gas is produced as a byproduct in industry and petrochemical plants, among others.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Deputy Industry Minister Park Il-jun promoted building large-scale hydrogen production plants in South Korea, as well as facilities for transport and storage both domestically and abroad. This is expected to create a complete system from production through distribution and use of the gas. South Korea’s efforts stem from its shift in energy production from nuclear power and coal to clean and sustainable energy sources. Hydrogen is an environmentally friendly alternative to fossil fuels because it releases only water during the combustion process. Hydrogen gas is produced as a byproduct in industry and petrochemical plants, among others.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Hyundai Engineering plans to secure rights to engineer, procure and construct microreactors in Canada, the U.S. and Poland by 2029. In doing so, the company is applying its experience from the MMR project in Chalk River, Canada. It is also working on technical improvements for the production of hydrogen in large quantities under a high-temperature process. Regarding nuclear power plant decommissioning and fuel rod disposal, Hyundai plans to participate in the design of interim storage facilities for the disposal of nuclear waste from the microreactors. In addition, the strategy calls for securing additional rights overseas for pyrolysis and treatment of radioactive waste. According to the company, it is prepared for the decommissioning and dismantling of nuclear power plants in South Korea. Based on Hyundai’s experience with the OYSTER research reactor in the Netherlands, the company hopes to gain further participation in similar projects in South Africa and Bangladesh.

We provide certification services for all product areas, including KC certification for consumer products and especially electronics, KC EMC certification for electronic products, and KCs certification for machinery, as well as KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Hyundai Engineering plans to secure rights to engineer, procure and construct microreactors in Canada, the U.S. and Poland by 2029. In doing so, the company is applying its experience from the MMR project in Chalk River, Canada. It is also working on technical improvements for the production of hydrogen in large quantities under a high-temperature process. Regarding nuclear power plant decommissioning and fuel rod disposal, Hyundai plans to participate in the design of interim storage facilities for the disposal of nuclear waste from the microreactors. In addition, the strategy calls for securing additional rights overseas for pyrolysis and treatment of radioactive waste. According to the company, it is prepared for the decommissioning and dismantling of nuclear power plants in South Korea. Based on Hyundai’s experience with the OYSTER research reactor in the Netherlands, the company hopes to gain further participation in similar projects in South Africa and Bangladesh.

We provide certification services for all product areas, including KC certification for consumer products and especially electronics, KC EMC certification for electronic products, and KCs certification for machinery, as well as KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Among the well-known exhibitors was Samsung Electronics, the world’s number one in smartphones and TVs, showcasing its latest gadgets such as the Galaxy S22 series devices and the foldable Galaxy Z Flip 3. LG Electronics also showed robots and gadgets for business customers in addition to its home appliances. An LG spokesperson elaborated further on the exhibits: For example, the LG CLOi ServeBot assistance robot greeted guests at the LG booth and explained the products on display. In the Smart Office Solutions area, LG introduced the LG One:Quick, a 4K touchscreen with camera, microphone and speaker for hospitals and clinical facilities. South Korean mobile operator KT presented smart cleaning robots for quarantine facilities and hospitals, as well as monitoring and control systems for road traffic, as part of its restructuring as a digital platform provider.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different authorities and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best contact for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs an more.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Among the well-known exhibitors was Samsung Electronics, the world’s number one in smartphones and TVs, showcasing its latest gadgets such as the Galaxy S22 series devices and the foldable Galaxy Z Flip 3. LG Electronics also showed robots and gadgets for business customers in addition to its home appliances. An LG spokesperson elaborated further on the exhibits: For example, the LG CLOi ServeBot assistance robot greeted guests at the LG booth and explained the products on display. In the Smart Office Solutions area, LG introduced the LG One:Quick, a 4K touchscreen with camera, microphone and speaker for hospitals and clinical facilities. South Korean mobile operator KT presented smart cleaning robots for quarantine facilities and hospitals, as well as monitoring and control systems for road traffic, as part of its restructuring as a digital platform provider.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different authorities and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best contact for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs an more.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Lotte Chemical identified hydrogen, battery materials, recycling and bio-plastics as new growth drivers and therefore decided to invest about 8 billion US dollars until 2030. The largest part will be invested in hydrogen energy, followed by battery materials and, with a comparatively small amount, recycling and bio-plastics. For this purpose, the hydrogen energy and battery materials business units will be newly founded.

The Hydrogen Energy Division is to secure the leading role in the entire value chain. This includes, among other things, the production, transport and distribution of hydrogen as well as securing the necessary supply of ammonia, which serves as a feedstock for hydrogen production. To this end, mainly so-called blue and green ammonia is to be imported from overseas by 2030, which will then be converted into a total of 1.2 million tonnes of hydrogen gas in Korea. Lotte Chemical is also promoting the expansion of the hydrogen filling station network as well as energy production with hydrogen by participating in corresponding joint ventures.

In battery materials, Lotte Chemical expects sales of US$3.84 billion by 2030 and hopes to become a major player within the electric vehicle, battery and materials supply chain. To this end, Lotte Chemical, together with its subsidiaries Lotte Fine Chemical and Lotte Aluminium, is investing directly or indirectly in four key battery precursors.

We offer certification services for all product areas, including KGS certification, KC EMC certification for electronic products and KCs certification for machinery, as well as KCs for explosion-proof products. We are at your disposal for all questions regarding Korea certifications.

Feel free to contact us any time if you need assistance or have any questions:

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Lotte Chemical identified hydrogen, battery materials, recycling and bio-plastics as new growth drivers and therefore decided to invest about 8 billion US dollars until 2030. The largest part will be invested in hydrogen energy, followed by battery materials and, with a comparatively small amount, recycling and bio-plastics. For this purpose, the hydrogen energy and battery materials business units will be newly founded.

The Hydrogen Energy Division is to secure the leading role in the entire value chain. This includes, among other things, the production, transport and distribution of hydrogen as well as securing the necessary supply of ammonia, which serves as a feedstock for hydrogen production. To this end, mainly so-called blue and green ammonia is to be imported from overseas by 2030, which will then be converted into a total of 1.2 million tonnes of hydrogen gas in Korea. Lotte Chemical is also promoting the expansion of the hydrogen filling station network as well as energy production with hydrogen by participating in corresponding joint ventures.

In battery materials, Lotte Chemical expects sales of US$3.84 billion by 2030 and hopes to become a major player within the electric vehicle, battery and materials supply chain. To this end, Lotte Chemical, together with its subsidiaries Lotte Fine Chemical and Lotte Aluminium, is investing directly or indirectly in four key battery precursors.

We offer certification services for all product areas, including KGS certification, KC EMC certification for electronic products and KCs certification for machinery, as well as KCs for explosion-proof products. We are at your disposal for all questions regarding Korea certifications.

Feel free to contact us any time if you need assistance or have any questions:

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Among manufacturers, LG Display dominates the OLED TV market and is capable of producing up to 7.42 million units annually. This increase only became possible with this year’s startup of a new factory in Guangzhou, China. Previously, the plant in Paju, South Korea, shipped about 4 million units annually. Rival Samsung Display, which makes OLEDs using its own QD (Quantum Dot) technology, is estimated to ship more than 10 million units this year. Pulsenews reports 21 manufacturers worldwide in the market for OLED displays or TV sets and therefore assumes a further spread of this technology.

KC certification for electronic products is a complex project that requires professional supervision at all stages. Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Among manufacturers, LG Display dominates the OLED TV market and is capable of producing up to 7.42 million units annually. This increase only became possible with this year’s startup of a new factory in Guangzhou, China. Previously, the plant in Paju, South Korea, shipped about 4 million units annually. Rival Samsung Display, which makes OLEDs using its own QD (Quantum Dot) technology, is estimated to ship more than 10 million units this year. Pulsenews reports 21 manufacturers worldwide in the market for OLED displays or TV sets and therefore assumes a further spread of this technology.

KC certification for electronic products is a complex project that requires professional supervision at all stages. Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Samsung, in addition to washers and dryers, has also adapted vacuum cleaners and air filters specifically for pet owners. For example, the Cube Air air filter can remove pet hair and odors from the air. The brand’s robotic vacuum cleaners monitor pet behavior and send an alert to the owner in case of abnormalities. According to a spokesperson, Samsung plans to expand its products for customers with pets in the future.

KC safety certification was established to ensure basic safety in the design and manufacture of machines used in households in Korea. The goal is to protect the health and safety of consumers by preventing accidents. We provide certification services for all product areas, including KC certification for consumer products and especially electronics, KC-EMV certification for electronic products, and KCs certification for machinery, as well as KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Samsung, in addition to washers and dryers, has also adapted vacuum cleaners and air filters specifically for pet owners. For example, the Cube Air air filter can remove pet hair and odors from the air. The brand’s robotic vacuum cleaners monitor pet behavior and send an alert to the owner in case of abnormalities. According to a spokesperson, Samsung plans to expand its products for customers with pets in the future.

KC safety certification was established to ensure basic safety in the design and manufacture of machines used in households in Korea. The goal is to protect the health and safety of consumers by preventing accidents. We provide certification services for all product areas, including KC certification for consumer products and especially electronics, KC-EMV certification for electronic products, and KCs certification for machinery, as well as KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

The revision mainly deals with non-compliant products, for whom penalty descriptions used to be rather vague. A focus lies on products that fall under the so-called Safety Confirmation (Type 2) in Korea. This category currently includes, e.g., baby clothing, sports equipment and bicycles for children, highchairs, skateboards, and toys.

Whenever manufacturers of KC certified products make incorrect statements when preparing test reports, untruthfully claim to be a “safety-friendly enterprise“, do not mark their products with the KC logo or apply the marking in a wrong way, the responsible Korean ministry may now demand rectification within six months (or less at its discretion) and suspend the existing certification of affected products for the corresponding period. Any marking of products with the KC logo is not permitted within this period.

In the case of intentional untruthful statements from manufacturers, testing and certification institutions will further be instructed to begin re-certification of the affected products after no less than a one-year suspension period.

An additional update faces the Korea Product Safety Management Agency, which will play a greater role in monitoring existing certifications in the future. It is to actively support the Ministry of Industry and Trade and the regional governments in the implementation of the relevant regulations. For this purpose, it may also impose the above-mentioned penalties on its own.

Children’s products, i.e., products intended primarily for babies and children up to the age of 12, are subject to strict regulations in Korea. Many products require a KC certificate. Depending on the risk they pose to the age group, products fall into one of three certification categories, some of which require product tests or even a factory audit. Violations of the import and marking regulations are strictly punished by the authorities and may lead to fines or the loss of acquired certifications in the worst case.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

The revision mainly deals with non-compliant products, for whom penalty descriptions used to be rather vague. A focus lies on products that fall under the so-called Safety Confirmation (Type 2) in Korea. This category currently includes, e.g., baby clothing, sports equipment and bicycles for children, highchairs, skateboards, and toys.

Whenever manufacturers of KC certified products make incorrect statements when preparing test reports, untruthfully claim to be a “safety-friendly enterprise“, do not mark their products with the KC logo or apply the marking in a wrong way, the responsible Korean ministry may now demand rectification within six months (or less at its discretion) and suspend the existing certification of affected products for the corresponding period. Any marking of products with the KC logo is not permitted within this period.

In the case of intentional untruthful statements from manufacturers, testing and certification institutions will further be instructed to begin re-certification of the affected products after no less than a one-year suspension period.

An additional update faces the Korea Product Safety Management Agency, which will play a greater role in monitoring existing certifications in the future. It is to actively support the Ministry of Industry and Trade and the regional governments in the implementation of the relevant regulations. For this purpose, it may also impose the above-mentioned penalties on its own.

Children’s products, i.e., products intended primarily for babies and children up to the age of 12, are subject to strict regulations in Korea. Many products require a KC certificate. Depending on the risk they pose to the age group, products fall into one of three certification categories, some of which require product tests or even a factory audit. Violations of the import and marking regulations are strictly punished by the authorities and may lead to fines or the loss of acquired certifications in the worst case.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.