Samsung SDI begins construction of the world’s first pilot plant to produce solid-state batteries

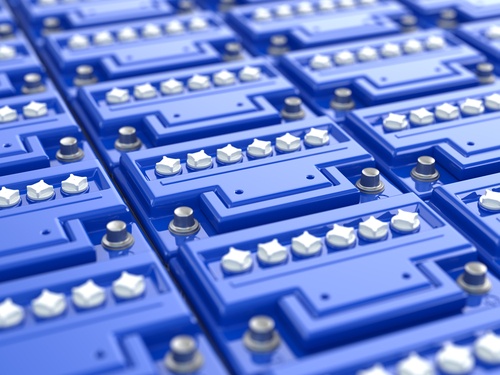

Samsung SDI could soon be one of the few vehicle battery manufacturers to operate a pilot plant for the production of solid-state batteries. To this end, ground was broken at the beginning of March for a factory for the pilot production of solid-state battery cells at Samsung’s research and development centre in Suwon, 34 kilometres south of Seoul. The South Korean company expects to mass produce next-generation batteries around 2027, three years ahead of domestic rivals LG Energy Solution Ltd. and SK On Co. Equipment and components necessary for the production of batteries require KC certification to a large extent in order to be sold on the Korean market. The plant, dubbed “S-Line” by Samsung, is seen as a milestone for an important technological advance, excellent quality and consistent growth, Chief Executive Officer Choi Yoon-ho said during groundbreaking ceremonies. The pilot plant covers 6,500 square metres and includes the latest production processes and facilities in battery manufacturing. Once construction is complete, Samsung says it will initially produce solid-state batteries for testing purposes. The findings from this are expected to accelerate the development of the so-called “Dream Battery”, with which Samsung hopes to extend its lead over domestic and foreign battery manufacturers.

Solid-state batteries have no separating layer between the cathode and anode and consist of solid electrolytes that store ions. In contrast, lithium-ion batteries have a liquid electrolyte that allows the lithium ions to move between the anode, separating layer and cathode. By omitting the flammable liquid electrolyte solution in lithium-ion batteries, solid-state batteries are considered safer, more durable and also allow for faster charging times. According to insiders from the battery industry, the solid-state batteries developed by Samsung SDI consist of sulphite electrolytes, for which the company has already secured corresponding technologies and patents. Samsung is currently in the final review of its technologies. This should be completed for small cells in 2023, medium and large cells should be ready for the market in 2025.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

The plant, dubbed “S-Line” by Samsung, is seen as a milestone for an important technological advance, excellent quality and consistent growth, Chief Executive Officer Choi Yoon-ho said during groundbreaking ceremonies. The pilot plant covers 6,500 square metres and includes the latest production processes and facilities in battery manufacturing. Once construction is complete, Samsung says it will initially produce solid-state batteries for testing purposes. The findings from this are expected to accelerate the development of the so-called “Dream Battery”, with which Samsung hopes to extend its lead over domestic and foreign battery manufacturers.

Solid-state batteries have no separating layer between the cathode and anode and consist of solid electrolytes that store ions. In contrast, lithium-ion batteries have a liquid electrolyte that allows the lithium ions to move between the anode, separating layer and cathode. By omitting the flammable liquid electrolyte solution in lithium-ion batteries, solid-state batteries are considered safer, more durable and also allow for faster charging times. According to insiders from the battery industry, the solid-state batteries developed by Samsung SDI consist of sulphite electrolytes, for which the company has already secured corresponding technologies and patents. Samsung is currently in the final review of its technologies. This should be completed for small cells in 2023, medium and large cells should be ready for the market in 2025.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

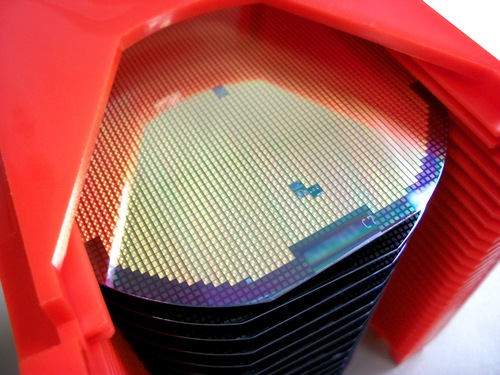

Germany’s Merck plans to manufacture semiconductor materials in South Korea

German company Merck plans to manufacture chemical mechanical polishing paste (CMP) in South Korea. Quality tests are currently underway with the CMP for customers in South Korea. Merck expects to begin shipments in the first half of 2022. CMP is a material used to polish and even semiconductor wafers. To do so, it is applied between the wafer and a rotating abrasive pad. Merck has previously built a CMP production facility in Pyeongteak, Gyeonggi Province. The research and development center and factory are located at the Korea Advanced Technology Center (K-ATeC), which opened in 2020. Equipment used in production facilities for such product categories in many cases requires KC certification to be approved in Korea. The composition of CMP depends on the specific customer. Therefore, there is a trend to develop this material locally together with the customer and also to manufacture it there. This also allows changes in composition to be implemented more quickly. Meanwhile, Japan’s Showa Denko has also started up a CMP factory in South Korea. Experts therefore expect increasing competition between foreign companies and domestic firms such as Dongjin Semichem and KCTech.

Merck also plans to produce so-called EUV rinse solution in South Korea. After exposure to extremely strong ultraviolet light (EUV), the residues are removed with this rinse solution. This requires a significantly different composition than the process using other light sources such as argon fluoride (ArF). Versum Materials, which Merck acquired in 2019, is also strengthening its presence in the Korean semiconductor market. Versum Materials supplies components with double patterning technology (DPT) to Samsung Electronics and other manufacturers. DPT prevents damage to semiconductors during microcircuit production. Samsung Electronics uses Versum Materials’ solution for about half of its production of DPT components.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

The composition of CMP depends on the specific customer. Therefore, there is a trend to develop this material locally together with the customer and also to manufacture it there. This also allows changes in composition to be implemented more quickly. Meanwhile, Japan’s Showa Denko has also started up a CMP factory in South Korea. Experts therefore expect increasing competition between foreign companies and domestic firms such as Dongjin Semichem and KCTech.

Merck also plans to produce so-called EUV rinse solution in South Korea. After exposure to extremely strong ultraviolet light (EUV), the residues are removed with this rinse solution. This requires a significantly different composition than the process using other light sources such as argon fluoride (ArF). Versum Materials, which Merck acquired in 2019, is also strengthening its presence in the Korean semiconductor market. Versum Materials supplies components with double patterning technology (DPT) to Samsung Electronics and other manufacturers. DPT prevents damage to semiconductors during microcircuit production. Samsung Electronics uses Versum Materials’ solution for about half of its production of DPT components.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Hyosung expands production of carbon fibers for hydrogen tanks

The Advanced Materials division of the South Korean Hyosung Group is expanding the production of carbon fibers. To this end, a third production line is being built to meet the increasing demand for the material in the manufacture of hydrogen tanks. In March 2022, Hyosung announced plans to invest the equivalent of $39 million in total to expand production capacity at its Jeonju plant from the current 2,500 tons to 9,000 tons. The company already invested in the expansion of the Jeonju production facility in 2020 and 2021. According to its own information, Hyosung is the only Korean company that can produce high-strength carbon fibers for industrial purposes, including gas and hydrogen tanks for vehicles. It began in 2011 with the development of the “Tansome” material made from carbon fibers, followed by series production in 2013. Hyosung plans to invest the equivalent of around $800 million in expanding the annual production volume of carbon fibers to 24,000 tons by 2028. If the plan is implemented by 2028, Hyosung would become the world’s third-largest producer of carbon fiber, accounting for about 10 percent of the global market, the company said. Gas tanks, pressure vessels and similar product categories need KGS factory approval in order to enter and be used on the Korean market. The Korea Gas Safety Corporation (KGS) is a government organization under the Ministry of Trade, Industry and Energy (MOTIE). Gas safety regulations in Korea began in 1974 with the passage of the Compressed Gas Control Act. In 1995, the Institute of High Pressure Gas Safety was established, and after several restructurings, the Korea Gas Safety Corporation (KGS) was established in 2001. One year later, KGS was affiliated with MOTIE. KGS was accredited as a Korean designated testing body in 2006 and was also accredited to perform KCs certification and testing of explosion-proof electrical equipment.

We offer certification services for all product areas, including KC certification for consumer products and especially electronics, KC EMC certification for electronic products, and KCs certification for machinery, as well as KCs for explosion safety products. We are available to answer any questions you may have about Korea certifications.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

The Korea Gas Safety Corporation (KGS) is a government organization under the Ministry of Trade, Industry and Energy (MOTIE). Gas safety regulations in Korea began in 1974 with the passage of the Compressed Gas Control Act. In 1995, the Institute of High Pressure Gas Safety was established, and after several restructurings, the Korea Gas Safety Corporation (KGS) was established in 2001. One year later, KGS was affiliated with MOTIE. KGS was accredited as a Korean designated testing body in 2006 and was also accredited to perform KCs certification and testing of explosion-proof electrical equipment.

We offer certification services for all product areas, including KC certification for consumer products and especially electronics, KC EMC certification for electronic products, and KCs certification for machinery, as well as KCs for explosion safety products. We are available to answer any questions you may have about Korea certifications.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

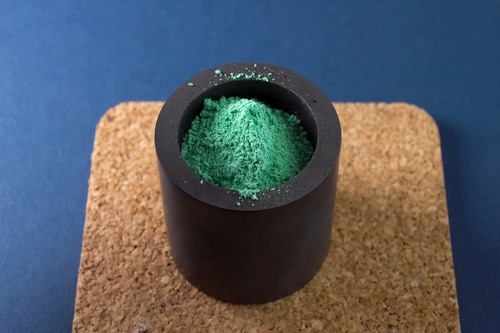

POSCO to build largest plant for production of battery electrolyte

POSCO Group, the world’s sixth-largest steelmaker, announced March 14 the start of construction of a solid electrolyte plant in Yangsan, about 420 km southeast of Seoul. This is the first investment by the new subsidiary POSCO Holdings, which was established in February to accelerate the development and production of environmentally friendly materials within the group. The holding company and JK, a Korean solid electrolyte producer, established the joint venture POSCO JK Solid Solution in February and planned to build the new production facility from that date. The joint venture will operate the plant, which will begin producing up to 24 tons of solid electrolyte annually in the second half of the year. The production volume, which can build 1,000 EVs respectively their batteries, is currently one of the world’s largest plants of its kind. Batteries and production-related components in many cases require KC Safety certification to be approved for trade and use in Korea. According to analysts, solid-state technology became the focus of industry interest after lithium-ion batteries, which are most commonly used in EVs, experienced problems with overheating and fire hazards. With solid-state batteries, charging is faster and the lack of electrolyte liquids reduces the risk of fire, the Wall Street Journal reported last September, following interviews with industry executives and analysts. POSCO’s new battery feedstock business model complements its existing main businesses: Steel, Lithium and Nickel, Hydrogen, Energy, Construction and Infrastructure, and Agricultural Biotechnology. After starting production of solid electrolytes, POSCO hopes to establish development and research collaborations with well-known battery manufacturers.

By 2030, the group aims to be able to produce 420,000 tons of cathode material and 260,000 tons of anode material and achieve a global market share of 20 percent. In early 2022, the company’s chemicals business, POSCO Chemical, announced plans to build a battery feedstock factory in Canada together with leading U.S. automaker General Motors (GM). To this end, the chemical company and GM will invest in the joint plant in Bécancour, Quebec, starting in 2023, where cathode material will be produced. The plant is expected to have an annual capacity of 30,000 metric tons.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

According to analysts, solid-state technology became the focus of industry interest after lithium-ion batteries, which are most commonly used in EVs, experienced problems with overheating and fire hazards. With solid-state batteries, charging is faster and the lack of electrolyte liquids reduces the risk of fire, the Wall Street Journal reported last September, following interviews with industry executives and analysts. POSCO’s new battery feedstock business model complements its existing main businesses: Steel, Lithium and Nickel, Hydrogen, Energy, Construction and Infrastructure, and Agricultural Biotechnology. After starting production of solid electrolytes, POSCO hopes to establish development and research collaborations with well-known battery manufacturers.

By 2030, the group aims to be able to produce 420,000 tons of cathode material and 260,000 tons of anode material and achieve a global market share of 20 percent. In early 2022, the company’s chemicals business, POSCO Chemical, announced plans to build a battery feedstock factory in Canada together with leading U.S. automaker General Motors (GM). To this end, the chemical company and GM will invest in the joint plant in Bécancour, Quebec, starting in 2023, where cathode material will be produced. The plant is expected to have an annual capacity of 30,000 metric tons.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Kia plans to build new plant in South Korea for purpose-built vehicles

After 25 years, South Korea’s second-largest automaker Kia plans to build a new plant to produce purpose-built vehicles, or PBVs. In doing so, the company aims to become the market leader in this emerging vehicle category by 2030. A PBV is an autonomous driving platform that can be equipped with different bodies and coachwork depending on customer preferences, according to Hyundai Motor Group, which owns Kia. Recently, Kia presented union members with plans to build a new plant where future models of PBVs and pickup trucks, among others, will roll off the assembly line. The last time Kia built a new production facility was in 1997, which was 25 years ago. It was an addition to the production line at the Hwaseong plant, about 80 kilometers south of Seoul. Production equipment and components for projects like these usually require KC certification, or specifically KC certification for electronic products, in order to be approved and distributed in Korea. Kia and its larger parent company Hyundai Motor Group have not expanded their production capacity in South Korea since 2000 because the domestic market is already saturated. Instead, they have focused on exporting vehicles. Kia’s decision to build a new plant for PBVs in South Korea was made because of the existing research and development center there. It is assumed that the company will invest several billion US dollars for the plant. However, an exact figure has not yet been given. Construction of the plant is scheduled to be completed in December 2024. Series production of the first Kia PBV is then scheduled for July 2025. This PBV has Level 4 self-driving features, an interior height of 1.8 meters, a mileage of 600,000 kilometers and automatic OTA updates. Initially, the PBV will be used to deliver goods. At a later date, there will also be a version as a robo-taxi as well as a larger vehicle for use in bus transport. Kia expects the global PBV market to grow to 20 million vehicles by 2030. That would correspond to around one third of all new vehicles sold.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Kia and its larger parent company Hyundai Motor Group have not expanded their production capacity in South Korea since 2000 because the domestic market is already saturated. Instead, they have focused on exporting vehicles. Kia’s decision to build a new plant for PBVs in South Korea was made because of the existing research and development center there. It is assumed that the company will invest several billion US dollars for the plant. However, an exact figure has not yet been given. Construction of the plant is scheduled to be completed in December 2024. Series production of the first Kia PBV is then scheduled for July 2025. This PBV has Level 4 self-driving features, an interior height of 1.8 meters, a mileage of 600,000 kilometers and automatic OTA updates. Initially, the PBV will be used to deliver goods. At a later date, there will also be a version as a robo-taxi as well as a larger vehicle for use in bus transport. Kia expects the global PBV market to grow to 20 million vehicles by 2030. That would correspond to around one third of all new vehicles sold.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

US-Korean renewable energy and digital infrastructure joint venture established

South Korea’s leading energy sector consulting firm, Energy Innovation Partners (EIP), recently formed a joint venture with an energy company and digital infrastructure developer. The joint venture plans to build renewable energy generation facilities and data centers in South Korea. This is expected to attract large and well-known technology companies as customers. According to information from various investment industry sources, EIP entered into the joint venture called “The Green Korea (TGK)” with U.S. energy infrastructure developer and investor “Diode Ventures.” Numerous components needed for renewable energy production must be KC certified for Korea in order to be imported and distributed there. TGK is to become a financial platform that develops renewable energy facilities and digital infrastructure for multinational technology companies. Under TGK’s plans, separate subsidiaries will be created for each type of energy, solar and wind, as well as for its data center business. The customers, technology companies with global operations and currently the largest consumers of renewable energy, are to meet their needs from local sources in the future. TGK’s business model is thus based on the global “RE100” initiative, which aims to encourage well-known companies to voluntarily use 100 percent green electricity by 2050. According to the “Climate Group,” more than 340 companies have already joined the RE100 initiative.

Large technology companies such as Amazon, Google, Meta and Microsoft currently purchase about 30 percent of the green power generated worldwide. As a result, TGK expects these companies to source their electricity from plants in Korea in the future. TGK is initially investing $2.5 billion over the next three years to build an environmentally friendly power plant in South Korea. It also plans to invest in a 40-megawatt data center at a local private university in North Chungcheong Province and a 150-megawatt solar plant with a local partner in South Jeolla Province. Numerous investment banks believe that TGK’s collaboration with world-renowned companies will increase the demand of renewable energy in South Korea.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

TGK is to become a financial platform that develops renewable energy facilities and digital infrastructure for multinational technology companies. Under TGK’s plans, separate subsidiaries will be created for each type of energy, solar and wind, as well as for its data center business. The customers, technology companies with global operations and currently the largest consumers of renewable energy, are to meet their needs from local sources in the future. TGK’s business model is thus based on the global “RE100” initiative, which aims to encourage well-known companies to voluntarily use 100 percent green electricity by 2050. According to the “Climate Group,” more than 340 companies have already joined the RE100 initiative.

Large technology companies such as Amazon, Google, Meta and Microsoft currently purchase about 30 percent of the green power generated worldwide. As a result, TGK expects these companies to source their electricity from plants in Korea in the future. TGK is initially investing $2.5 billion over the next three years to build an environmentally friendly power plant in South Korea. It also plans to invest in a 40-megawatt data center at a local private university in North Chungcheong Province and a 150-megawatt solar plant with a local partner in South Jeolla Province. Numerous investment banks believe that TGK’s collaboration with world-renowned companies will increase the demand of renewable energy in South Korea.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Hyundai Motor introduces first garbage truck with hydrogen engine

Back in December 2021, South Korea’s Hyundai Motor Group unveiled the world’s first hydrogen-powered garbage truck in a YouTube video. The truck’s body is no different from existing garbage trucks with diesel engines, but it has a storage tank for hydrogen and two fuel cells. These come from the Hyundai Nexo, the world’s only fuel cell-powered SUV. Thanks to the specially developed engine, the truck can climb steep inclines with ease despite being loaded with 4.5 tons of waste. Since January 2022, the garbage truck has been in service with the city of Changwon, South Gyeongsang Province. To be approved for the Korean market, pressurized products such as hydrogen storage tanks require KGS approval. In general, vehicles powered by hydrogen do not emit exhaust gases. Therefore, city sanitation workers who work on the garbage truck do not have to worry about exhaust gas pollution. Noise pollution has also been reduced by 40 percent thanks to the electric motor, and only a low hum from the drive can be heard. The water produced during operation in the fuel cell is collected in a tank and is used by employees for cleaning during and after work. After evaluating customer requirements, Hyundai Motor Group plans to build more special vehicles with hydrogen engines.

The Korea Gas Safety Corporation (KGS) is a government organization under the Ministry of Trade, Industry and Energy (MOTIE). Gas safety regulations in Korea began in 1974 with the passage of the Compressed Gas Control Act. In 1995, the Institute of High Pressure Gas Safety was established, and after several restructurings, the Korea Gas Safety Corporation (KGS) was established in 2001. One year later, KGS was affiliated with MOTIE. KGS was accredited as a Korean designated testing body in 2006 and was also accredited to perform KCs certification and testing of explosion-proof electrical equipment.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KGS factory registration, KC, KC EMC, KCs and KCs for explosion safety products.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

In general, vehicles powered by hydrogen do not emit exhaust gases. Therefore, city sanitation workers who work on the garbage truck do not have to worry about exhaust gas pollution. Noise pollution has also been reduced by 40 percent thanks to the electric motor, and only a low hum from the drive can be heard. The water produced during operation in the fuel cell is collected in a tank and is used by employees for cleaning during and after work. After evaluating customer requirements, Hyundai Motor Group plans to build more special vehicles with hydrogen engines.

The Korea Gas Safety Corporation (KGS) is a government organization under the Ministry of Trade, Industry and Energy (MOTIE). Gas safety regulations in Korea began in 1974 with the passage of the Compressed Gas Control Act. In 1995, the Institute of High Pressure Gas Safety was established, and after several restructurings, the Korea Gas Safety Corporation (KGS) was established in 2001. One year later, KGS was affiliated with MOTIE. KGS was accredited as a Korean designated testing body in 2006 and was also accredited to perform KCs certification and testing of explosion-proof electrical equipment.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KGS factory registration, KC, KC EMC, KCs and KCs for explosion safety products.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Introduction to “Technical Certifications in China, India, Korea”

In June and July 2022, the Hanover Chamber of Commerce and Industry (IHK) will offer a series of online seminars created and conducted by us, MPR International.

The seminars are aimed at quality management representatives of industrial companies as well as project engineers or project managers responsible for certifications of products for China, India or Korea.

The free introductory event on 18.05.2022, 9:15-10:00 a.m. provides an overview of the certification landscape of the respective countries, which will be covered comprehensively and in depth in the individual seminars and is intended to give an insight into what you can expect in the individual seminars.

Registration is required for the introductory event.

The in-depth seminars will focus on the following countries and industries:

- Technical Certifications in China Automotive (2-part): – Part 1: Wed, 22.06.2022, 9:00-12:00 hrs. – Part 2: Fri, 24.06.2022, 9:00-12:00)

- Technical Certifications in India (1-part): – Mon, 06/27/2022, 9:00am-12:00pm.

- Technical Certifications in South Korea (1-part): – Tue, 06/28/2022, 9:00-12:00 (duration 3 hours)

- Technical Certifications of Industrial Products in China (2-part): – Part 1: Tue, 07/12/2022, 9:00am-12:00pm. – Part 2: Wed, 07/13/2022, 9:00am-12:00pm

At MPR International, we have been assisting hundreds of companies worldwide with certifications for the Chinese, Korean and Indian markets since 2005.

If you would like to receive more information about any of the certifications in advance, please visit our website or contact us by email or at +49692713769259.

The company Korea Zinc plans to double the production of raw materials for batteries

South Korea’s Korea Zinc Co. is considered the country’s leading lead and zinc smelter and plans to double its production capacity of nickel sulfate. The raw material is considered an important component of battery cathodes. The company expects increasing demand from battery manufacturers due to growth in the EV market. A subsidiary of Korea Zinc, Korea Energy Materials Co. (KEMCO), is responsible for producing the nickel sulfate. According to industry insiders, KEMCO purchased a roughly 16,000-square-meter plot of land to expand its production capacity from the current 50,000 tons annually to 80,000 to 100,000 tons. Production material for battery manufacturing in most cases requires KCs certification, or KCs certification for explosion-proof products, to be used in Korea. Nickel sulfate is considered a major precursor material for the production of cathodes and is one of the four components of lithium-ion batteries. It is produced by adding sulfuric acid to high-purity nickel. The resulting material can be used by battery manufacturers for cathodes without further processing steps. This speeds up the production process and reduces costs. By expanding its production capacity, Korea Zinc hopes to increase its market share in the global battery market. The industry already produces 90 percent of its cathodes from nickel sulfate. With these batteries, the range could be increased and production costs reduced. On average, the battery of an EV requires between 50 and 100 kilograms of nickel. Thus, after the expansion, Korea Zinc’s 100,000-ton facility can meet the needs of 1,000 to 2,000 EVs annually.

Based on the Occupational Health and Safety Act, the Korea Occupational Safety and Health Agency (KOSHA) requires KCs Ex certification of explosion-proof electrical components. Korea has been conducting Ex approvals since 1992. KCs certification was established to ensure basic safety in the design and manufacture of hazardous machinery and protective equipment in hazardous workplaces in Korea. The goal is to protect the health and safety of workers by preventing accidents. We provide certification services for all product areas, including KC certification for consumer products and especially electronics, KC-EMV certification for electronic products, and KCs certification for machinery, as well as KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Nickel sulfate is considered a major precursor material for the production of cathodes and is one of the four components of lithium-ion batteries. It is produced by adding sulfuric acid to high-purity nickel. The resulting material can be used by battery manufacturers for cathodes without further processing steps. This speeds up the production process and reduces costs. By expanding its production capacity, Korea Zinc hopes to increase its market share in the global battery market. The industry already produces 90 percent of its cathodes from nickel sulfate. With these batteries, the range could be increased and production costs reduced. On average, the battery of an EV requires between 50 and 100 kilograms of nickel. Thus, after the expansion, Korea Zinc’s 100,000-ton facility can meet the needs of 1,000 to 2,000 EVs annually.

Based on the Occupational Health and Safety Act, the Korea Occupational Safety and Health Agency (KOSHA) requires KCs Ex certification of explosion-proof electrical components. Korea has been conducting Ex approvals since 1992. KCs certification was established to ensure basic safety in the design and manufacture of hazardous machinery and protective equipment in hazardous workplaces in Korea. The goal is to protect the health and safety of workers by preventing accidents. We provide certification services for all product areas, including KC certification for consumer products and especially electronics, KC-EMV certification for electronic products, and KCs certification for machinery, as well as KCs for explosion-proof products. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Sustainable fossil fuel production becomes necessary for South Korean oil refinery operators

For decades, South Korea’s four major oil refinery operators set an example for the entire industry in terms of upgrading their facilities. These multi-billion dollar investments often resulted in higher costs and lower profits. Leading refiner SK Energy, as well as local giants GS Caltex Corp, S-Oil Corp and Hyundai Oilbank Co, have invested large sums in upgrading their facilities to produce high-quality end products such as gasoline from low-cost crude. Hyundai Oilbank’s expansion or upgrade rate of 40.6 percent is among the highest in the industry worldwide, followed by GS Caltex at 34.4 percent, S-Oil at 33.8 percent and SK Energy at 24.9 percent. This compares with refineries in China and Japan at around 20 percent, and plants in Russia and Saudi Arabia at 10 percent. Products from the oil and gas industry require certification to a large extent on the Korean market. Gas and pressure vessels usually require KGS factory approval. With the global trend toward sustainable energy production, so-called ESG (environmental, social, governance) goals have also become standard in the energy sector. Refinery operators around the world are looking for new revenue streams beyond the traditional oil business to continue making profits. South Korean companies are even considering changing their corporate name to move away from the image of the dirty oil business and invest more in renewable energy. Still, operators must continue to invest in their plants to remain competitive, analysts say.

Analysts believe companies have no option but to continue upgrading their facilities, as more than two-thirds of revenues come from refining operations. To boost profits, some refiners are now sourcing cheaper crude from South America. For example, Hyundai Oilbank last year bought Colombia Castilla, an oil grade that is inferior to oil from the Middle East but costs about 10 percent less. As a result, the share of oil imported from countries other than the Middle East rose from 45 to 65.3 percent and 18.2 to 25.3 percent for both Hyundai and GS Caltex, respectively. Meanwhile, SK Innovation, the parent company of SK Energy, has announced plans to become an environmentally friendly company in the long term and to invest about $24 billion in restructuring projects by 2025.

We offer certification services for all product areas, including KGS factory approvals for high-pressure and gas appliances. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

With the global trend toward sustainable energy production, so-called ESG (environmental, social, governance) goals have also become standard in the energy sector. Refinery operators around the world are looking for new revenue streams beyond the traditional oil business to continue making profits. South Korean companies are even considering changing their corporate name to move away from the image of the dirty oil business and invest more in renewable energy. Still, operators must continue to invest in their plants to remain competitive, analysts say.

Analysts believe companies have no option but to continue upgrading their facilities, as more than two-thirds of revenues come from refining operations. To boost profits, some refiners are now sourcing cheaper crude from South America. For example, Hyundai Oilbank last year bought Colombia Castilla, an oil grade that is inferior to oil from the Middle East but costs about 10 percent less. As a result, the share of oil imported from countries other than the Middle East rose from 45 to 65.3 percent and 18.2 to 25.3 percent for both Hyundai and GS Caltex, respectively. Meanwhile, SK Innovation, the parent company of SK Energy, has announced plans to become an environmentally friendly company in the long term and to invest about $24 billion in restructuring projects by 2025.

We offer certification services for all product areas, including KGS factory approvals for high-pressure and gas appliances. We are available to answer any questions you may have about Korea certifications.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.