Exports of electric cars from South Korea increased sharply

According to a recent report, exports of electric cars from South Korea increased by 66 percent year-on-year. As a result, this sector bucked the general negative trend in the automotive industry due to the Covid 19 pandemic. The export volume of electric cars was around $3.9 billion in 2020, overtaking the value of hybrid cars for the first time, which was $2.5 billion. The data was compiled by the Korean International Trade Association. Electric cars accounted for more than half of all green car exports, which totaled US$7.1 billion in value.

Europe was the largest market for South Korea’s eco-friendly cars, accounting for 68 percent of the total. Worldwide, South Korea also shipped 955 fuel cell vehicles in 2020. This represents 26.3 percent growth over the previous year. The country was the fourth largest exporter of electric cars in the January-September 2020 period, according to the trade association. The value for exports of motor vehicles from South Korea in general reached $37.4 billion in 2020, a loss of 13.1 percent from the previous year and most likely attributable to the Covid 19 pandemic. These data were announced by the Korean Ministry of Trade, Industry and Energy.

The automotive industry in South Korea ranks 7th in the world in both production figures and exports. The largest manufacturers, ranked by global sales, are Hyundai, Kia, GM Korea, Ssangyong and Renault Samsung. Hyundai and Kia are unchallenged in the top two spots with 59,501 and 41,481 vehicles sold in January 2021, respectively. So follows third-placed GM Korea with only 6106 units. For the electric car sector, Hyundai also signed a memorandum of understanding with the South Korean government in February. Together with other companies, LG Energy Solution and KST Mobility, electrically powered cabs are to be tested. Hyundai will supply the vehicles, the Kona Electric, and take care of the maintenance and replacement of the batteries; LG Energy Solution will provide the charging stations and KST Mobility will operate the cabs.

MPR International GmbH will be pleased to advise you regarding Korea certification in the automotive sector. We have already successfully accompanied many large automotive suppliers and vehicle manufacturers with locations in Korea in their certification projects and have been supporting these companies for several years. Our experts are available at any time by phone or e-mail to answer your questions regarding a pending Korea certification.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Samsung C&T unveils next-generation artificial intelligence in its smart home

Samsung’s construction business unit, Samsung C&T, plans to introduce next-generation smart home technology based on artificial intelligence (AI). The company plans to launch this technology next year at the earliest. On Feb. 15, Samsung opened the Raemian Artificial Intelligence (RAI) Life Hall, an upgrade of the previous Raemian Home Lab-Smart Life Hall. The venue showcases AI technology for a more convenient everyday life. The newly opened demonstration building includes services that use future technologies such as AI, robots and drones. Dedicated spaces such as a home office and fitness area have also been set up. Samsung C&T expects these technologies to be ready for the market within 2021, when the trial process is completed.

The building is essentially divided into public and confidential areas. The public area consists of a smart parking lot and some rooms of an apartment. Samsung C&T has installed a parking guidance system that directs residents to a free parking space near their apartment as well as sends a robot to the parked car, which helps one carry groceries. The cars are recognized by cameras and license plate recognition systems. At the entrance to the apartment is a camera for facial recognition as well as a thermal imaging function. Other surveillance cameras film the growth of plants in the shared smart farm and transmit them directly to each apartment.

In the public area, robots guide visitors to the individual rooms, while in the in-house café, robots prepare drinks and serve guests. In a show apartment, Samsung applies the new AI to existing smart home functions. The artificial intelligence detects and learns the habits of the residents and automatically controls the corresponding functions in the home. Controls by the AI include lighting, temperature and entertainment, which are switched according to patterns for eating, relaxing and sleeping. In light of the Covid 19 pandemic and an increase in time spent at home, Samsung C&T has also integrated a home office/homeschooling area into the home. In addition, a multi-function room for hobbies, fitness and home theater has been added.

To import or sell electronic equipment in South Korea, this is subject to KC certification (also called KC-Mark). The KC-Mark or KC certificate is roughly equivalent to the European CE mark and applies to 730 different products. KC certification, or Korea Certification, is primarily about identifying and containing a potential risk to consumer health and safety. We will be pleased to provide you with non-binding advice regarding Korea Certification and would be delighted to carry it out for you.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Korea’s government expands support for foreign companies

The government announced an expansion of support for foreign companies based or doing business in South Korea in early February. In light of the pandemic, the country is encouraging investment, particularly for digital and “green” industries in line with a major investment project, the “New Deal” initiative. Trade Minister Yoo Myung-hee said at a meeting with the Korea Foreign Company Association (FORCA) that despite the challenges posed by Covid-19, foreign investors have increased their involvement in semiconductors and chips, biotechnology, and green vehicles and batteries. The minister pointed out that in 2020, foreign firms accounted for 5.6 percent of the workforce as well as 18.6 percent of imports.

Overall, foreign direct investment (FDI) in Korea in 2020 declined 11 percent year-on-year due to the coronavirus pandemic and global recession. As the fourth largest economy in Asia, South Korea received $20.7 billion in foreign investment last year, down from $23.3 billion in 2019. Still, this is the sixth consecutive year Korea has secured more than $20 billion in investment. Later this year, the South Korean government will offer more opportunities for business activities by foreign companies in line with the “New Deal” initiative. The “New Deal” initiative, unveiled last year, consists of four pillars: Promoting digital and “green” businesses; strengthening job security and social benefits; and balanced regional development. The government will announce further details for foreign direct investment (FDI) promotion in March.

South Korea is considered one of the most important and innovative industrialized nations in the world. To gain market access to this highly technological country, products imported into South Korea must be tested and certified.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

South Korean Car Market Strong During Last Year

Despite falling numbers in global automobile sales, which declined by 14 percent last year, the South Korean market proved to remain strong with a growing number of new registrations.

Registrations have increased by 6.2 percent to 1,905,972, exceeding the historical landmark of 1.9 million. This makes the South Korean market the only global top 10 market with increases in domestic sales, managing to rise from 12th to ninth spot regarding market size.

The market share of imported cars has increased from 15.3 percent to 15.9 percent regarding sales volume, and up to 28 percent regarding sales value, with the number of imported cars exceeding 300,000. Standard vehicle selling prise has increased from 32.9 million won to 35.9 million won.

in 2020, the market share of electric and hyrid vehicle sales broke the 10 percent mark for the first time ever, with the hybrid car sales volume exceeding 173,000 and the electric vehicle sales volume reaching 5,841.

Many automotive and other products might fall under one of Korea’s various certification schemes.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

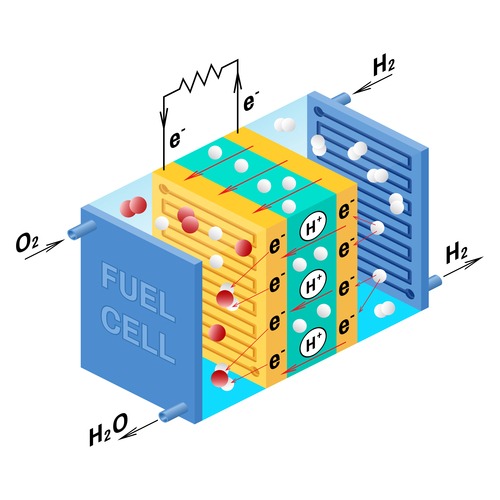

SK E&C begins production of environmentally friendly fuel cells

The new production facility, named Bloom SK Fuel Cell Plant, is a joint venture between SK E&C and U.S.-based Bloom Energy, a global manufacturer of fuel cells. The joint venture was established in January last year to produce so-called SOFCs (solid oxide fuel cells) in South Korea. SK E&C owns 49 percent of the company, while Bloom Energy owns the remaining 51 percent. The two companies began trial production of SOFCs in July. They plan to expand production capacity from 50 MW in 2021 to 400 MW in 2027. The first fuel cells will be delivered to a power plant, which is scheduled to begin operations in January 2021. The power plant will then have the world’s most powerful fuel cells.

At the opening ceremony, SK E&C announced two other major achievements of projects using SOFCs. The first was winning an engineering, procurement and execution project at Equinix, one of the leading data center operators in the United States. It involves the construction of a 6.4 MW SOFC plant at an Equinix data center in San Jose, California. Groundbreaking is scheduled for April 2021, with commissioning eight months after completion of construction. The second advance is the signing of a memorandum of understanding between SK E&C, Bloom Energy and SK Advanced for a pilot project to apply hydrogen as a waste product from the chemical industry and use it to power fuel cells. SK Advanced’s PDH plant in Ulsan, South Korea, where the company produces propylene and other gases, was selected as the site. To that end, the companies are building an SOFC pilot plant that is scheduled to begin operations in April 2021 and will study commercial applications of the process over the course of a year.

Solid oxide fuel cells (SOFCs) are the world’s most effective power generation for distributed applications. The fuel cell uses liquefied natural gas and generates electricity during a reaction of hydrogen and oxygen. The process far outperforms conventional fuel cells and generates environmentally friendly electricity without fine dust emissions and on a very small footprint. Numerous SOFCs are already in operation in the U.S., including at Walmart and Home Depot stores and the Morgan Stanley and Softbank buildings in New York.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

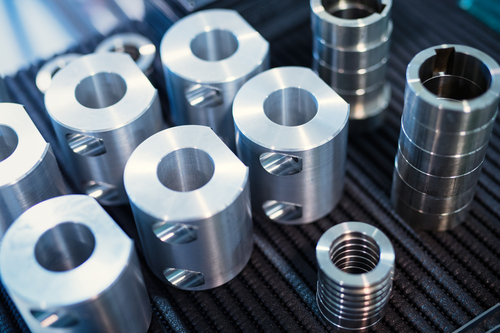

South Korean steel producer POSCO launches first environmentally friendly free-cutting steel

South Korean steelmaker POSCO announced through a press release in August 2020 that the company successfully started mass production of lead-free free cutting steel in June and is now looking for customers in the automotive and IT industries. The new material is called POSCO Graphitic Steel for Machinability (PosGRAM) and is the world’s first graphite-based free cutting steel. Free-cutting steel is often offered as rod-like material and enables fast machining in appropriate machines and cleaner surfaces than conventional steel. It is typically used for metal parts of vehicles and IT products that have complex geometries or have particularly high accuracy requirements.

Current steels of this type often contain lead, which is cheaper than other additives but poses health and environmental problems. During alloying in the steel mill, toxic lead vapors are released from the molten metal and special equipment must be used to extract and capture the vapors. As a result, lead-alloyed free-cutting steels are no longer produced in large quantities. Due to increasing environmental concerns, global standards have been adopted, including by the EU, which reduce the amount of lead in steels to 0.1 percent. However, since no adequate substitutes for lead have yet been found for free-cutting steel, up to 0.35 percent lead is permitted here.

POSCO reiterated the significance of mass production of PosGRAM, which replaces lead with graphite without sacrificing processing speed. PosGRAM has clean and even surfaces in any cutting direction and can be used in electromechanical components because it is easy to magnetize. POSCO has been researching the development of graphite free cutting steel since 2017 and began mass production in 2020. The company has been selling the steel to some customers since June. Annual global demand for free-cutting steel is an estimated 1 million tons, half of which is lead-based products. Previously, there was no company in South Korea producing lead-free free-cutting steel, so they imported an average of 23,000 tons annually from abroad, including Japan. With the new PosGRAM steel, POSCO expects to replace imported steels as far as possible and contribute to the competitiveness of the domestic industry. Steel products in South Korea require certification with the KC mark or KC certificate, which is roughly equivalent to the European CE mark and currently applies to 730 different products. MPR International GmbH – Korea Certification is available to answer your questions regarding Korea certification at any time and without obligation.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

LG Chem produces new type of battery for Tesla’s electric cars

The share price of South Korea’s LG Chem rose 3.57 percent on Oct. 22, 2020, the day Tesla announced higher profits than the market expected. Industry experts suspect a high impact of the Tesla announcement on LG Chem’s share price. Industry insiders citing the reason as LG Chem’s development of a new battery for electric vehicles, which Tesla unveiled at the so-called “Battery Day” in September 2020 without mentioning the name of the manufacturer or supplier. Meanwhile, LG Chem is preparing for a surge in Tesla’s orders, tripling its cylindrical battery cell production capacity from the current 20 GWh to 60 GWh by 2023.

The speculation that LG Chem will develop a new battery type and become one of Tesla’s main suppliers is based on two reports. On October 21, 2020, Jang Seung-se, vice chairman of LG Chem, reported that his company is working on the development of cylindrical battery cells, which have a fivefold higher energy density and six times more capacity. These specifications exactly match Tesla’s Type 4680 battery, which Tesla CEO Elon Musk unveiled in September. Initially, Tesla wanted to produce the new Type 4680 battery cells itself. Afterwards, however, it turned out that this would exceed Tesla’s current production capacities and that it would also not be possible to build a new production facility within a year.

Tesla estimates that the required quantity of Type 4680 batteries in 2020 will have a capacity of 100 GWh. These could then be installed in around 1.3 million electric cars annually. LG Chem, the world’s largest battery manufacturer, currently has a total annual production capacity of 100 GWh but was able to increase this to 120 GWh by the end of 2020, according to the company. Nearly all of the cylindrical battery cells for electric vehicles that LG Chem produces are installed in Tesla models. In order to supply other manufacturers besides Tesla or to avoid shortages, LG Chem plans to expand its total annual production capacity to 260 GWh by 2023. Electric car components, which include batteries, must undergo certification for the KC mark or KC certificate in Korea. Our experts are always available to answer any questions without obligation.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Everyday objects with OLED displays move a step closer

The eye-catcher of the exhibition is the OLED display technology that LG has installed in numerous interior design and everyday objects in the show house. The living of the future can be seen at LG’s Science Park in the South Korean capital Seoul. The technology in the bedroom is particularly innovative. Built into the footboard of the bed is a 55-inch OLED screen that hides discreetly and can be raised automatically. In the background, sensors analyze sleep behavior and quality and show the result every morning. In addition, the user can display other information such as weather, schedule and news. The screen can be adjusted in height depending on the viewing angle, offering an optimal viewing experience from any position.

The LG Display business unit is working on developing the next generation of OLED displays to expand its product range and differentiate itself from the competition. In particular, the company plans to offer screens for use in the home environment. LG OLED displays are narrower than traditional smart TVs or flat-panel displays, plus they don’t require backlighting and use innovative materials that make them more flexible and durable. LG is currently developing OLED screens from 55 to 88 inches, which are only 1 mm narrow. In the showroom, for example, there is a mirror made of an OLED screen on which users can virtually try on new clothes and then order them directly online. The living room of the show house features a curved OLED screen on the ceiling as well as screens that can change their bend or orientation depending on the viewing angle.

Through the exhibition currently taking place, LG hopes to establish strategic partnerships in the B2B sector with construction companies, home appliance manufacturers, furniture and interior design companies. Collaboration is expected to create synergy in the home interior sector and further expand LG’s competitiveness in the display industry. “The new OLED showroom is part of our innovation initiative, in which LG aims to differentiate itself from conventional TV and IT products and expand into new business areas,” said Alex Kwon, head of business development, LG OLED displays division. To be imported or sold in South Korea, electronic devices are subject to KC certification (also called KC Mark). The KC-Mark or KC certificate is roughly equivalent to the European CE mark and applies to 730 different products. KC certification, or Korea Certification, is primarily about identifying and containing a potential risk to consumer health and safety. We will be pleased to advise you on Korea Certification without obligation and to eventually carry it out for you.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

South Korean telecommunications companies reduce dependence on their core business

The three largest telecom companies in South Korea, SK Telecom (SKT), KT and LG Uplus, are looking for new business areas and growth industries outside their usual core business, the conventional telecom sector. The companies see difficulties in continuing their businesses in the telephony sector successfully in the post-Corona era and the entry into the so-called “Fourth Industrial Revolution”. According to their own statements, the aforementioned companies have already upgraded or supplemented their conventional telephony services with artificial intelligence, Big Data and cloud services.

A spokesperson for the telecom industry confirmed the shift within the companies toward providers of digital services of all kinds, such as online shopping, web and server hosting, streaming and contactless payment processing. For example, SK Telecom recently changed its company name to SKT to reduce the reference to telecommunications. KT (Korea Telecom) calls itself an “AI company” or “digital platform provider” in hopes of attracting more business customers. LG Uplus dropped the word “telecom” from its company name long ago, and its businesses in other areas outside of telephony have shown good growth rates in recent years.

SKT plans to transform itself into a global tech company with growth in media, IT security and commerce. The basis for this is the existing Information and Communications Technology division. Plans call for the new business areas to account for more than 35 percent of sales in the future. This year, the media sector has already posted a 20 percent year-on-year increase in sales. Here, SKT has bought up the provider T-broad and now offers IPTV services. The number of subscribers increased by 129,000 in the previous quarter. SKT is also planning to establish a platform for mobility and positioning services based on its popular T Map system. A strategic partnership with the cab service Uber is under discussion here.

South Korea is considered one of the most important and innovative industrial nations in the world. To gain market access to this highly technological country, products imported into South Korea must be tested and certified. The KC mark or certificate is roughly equivalent to the European CE mark and applies to 730 different products, including many electronic products. For products with a radio module, KC EMC certification is also required. MPR International GmbH has solid experience in Korea certification and competent local partners.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

LG Chem further expands its leading position in the global automotive battery market

According to market observers from SNE Research, LG Chem was able to secure the top position in the global market for automotive batteries in the months January to September 2020 with a market share of 24.6 percent. The batteries delivered by LG Chem during this period had a total capacity of 19.9 gigawatt hours (GWh). Competitor Samsung SDI was able to gain a place in the global comparison and is now in fourth position with a market share of 6.2 percent or 5.0 GWh. SK Innovation rose by three places to sixth rank. The market share is 4.4 percent or 3.5 GWh. The combined market share of these three South Korean companies is 35.1 percent, more than double last year’s 16.2 percent.

While Korean battery manufacturers reported satisfactory business figures, companies from Japan and China reported a slowdown in sales. CATL from China was number one worldwide in 2019 with a market share of 26.5 percent, but lost its leading role and fell to 23.7 percent in 2020. Panasonic from Japan was second in 2019 with 25.0 percent market share, but fell to third place this year with 19.5 percent. The declines at Chinese and Japanese companies are due to weaker demand for electric vehicles in China and the U.S. during the first half of 2020. Overall, the battery capacity of all electric vehicles registered worldwide in the period January to September fell from 81.9 in 2019 to currently 80.8 GWh.

In the meantime, LG Chem announced at a shareholder meeting on October 30, 2020, that it will spin off its battery business into a new company LG Energy Solution. The shareholders have already approved the plan. The Group plans to increase LG Energy Solution’s revenues to USD 26.9 billion by 2024. Components of electric vehicles, which include batteries, must undergo certification in Korea. The KC mark or KC certificate is roughly equivalent to the European CE mark and applies to 730 different products, the scope of which changes frequently. We offer certification services for all product areas. We have developed particular expertise in the automotive, electrical, mechanical engineering, telecommunications and IT sectors.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.