LG Uplus plans introduction of autonomous robot next year

LG Uplus Corporation, a leading South Korean mobile operator, said last Friday it plans to launch a self-operating industrial robot with 5G connectivity next year. The robot, which was developed in cooperation with Unmanned Solution, a company specializing in autonomous driving, recently demonstrated its capabilities within a refinery. The refinery belongs to Hyundai Oilbank and is located in Seosan, 150 km south of the capital Seoul. According to LG Uplus, during the demonstration the robot was able to move within an accuracy of 10 centimeters and performed routine tasks such as measuring and reading temperatures of the plant equipment.

The robot, which is manufactured by Unmanned Solutions, can calculate its location and movement by using position data from the high-speed 5G wireless network. It benefits from the extremely short latency of the 5G network. A spokesman for LG Uplus said that this autonomous robot will be part of the basic equipment of a refinery in the future. The spokesman added that a robot is preferable to human workers, particularly from a safety perspective. LG Uplus plans to complete the test operation by the end of this year and bring the robot to market next year.

LG Uplus Corp. is a South Korean mobile phone provider owned by LG Corporation and parent company of LG Electronics. In addition to mobile communication, LG Uplus offers further services through subsidiaries: BankOn is the most popular mobile banking service in South Korea, MusicOn is a music streaming service. LG Uplus has its own infrastructure as well as landline telephone network, broadband internet with fiber optics and television over the internet (IPTV). Electronic devices and systems for mobile communication must undergo certification in Korea. Among others, there is the KC certification for consumer products and especially electronics as well as the KC EMC certification for electronic products. MPR International GmbH – Korea Certification is represented by its own subsidiaries at five locations and thus completely covers the demand for certification services for the South Korean market. We offer certification services for all product areas. We have developed special expertise in the automotive, electrical, mechanical engineering, telecommunications and IT sectors. Our experts are always available to answer your questions without obligation.

If you need assistance or have any questions, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

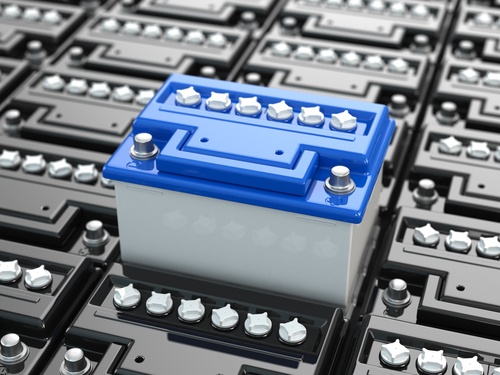

Korean battery manufacturers showed mixed reactions to Tesla’s new product

The three largest Korean battery manufacturers, which have a global market share of 30 percent in automotive batteries, are uncertain about Tesla’s new product launch, but at the same time have particular expectations of the new technology. The core of Tesla’s new technology is the “Roadrunner Project”, a blueprint for battery manufacturing. At Battery Day, industry experts saw a presentation of the current status of the project, which aims to reduce manufacturing costs and increase energy density and durability. Tesla also gave an outlook on future production processes for automotive batteries. The greatest strength of Tesla, the world’s number 1 in electric vehicles, is the vertical integration of semiconductors, electronic control systems and vehicle components used in electric vehicles.

Despite all the euphoria, Tesla is currently dependent on external suppliers for vehicle batteries. The possibility of an in-house production of solid state batteries at Tesla gained substance after taking over Maxwell, a battery manufacturer. However, analysts do not yet see Tesla’s own batteries ready for series production due to technical challenges. Experts therefore speculate that Tesla is working on a new technology for lithium ion phosphate (LFP) batteries in cooperation with the Chinese battery manufacturer CATL.

Although the three largest Korean battery manufacturers are concerned about Tesla’s entry into the automotive battery market, it is also hoped that this will have positive effects in terms of a growing market and increasing acceptance of electric vehicles. A spokesman for Korean industry said: “Tesla has triggered a boom for electric vehicles and their entry into the battery business will also bring benefits to Korean companies. Competition will boost the market and bring new technologies to market faster”. An industry insider also urged prudence: “Even though Tesla will introduce innovative technologies, it will still be difficult to compete with the decades of development work and experience of specialized battery manufacturers.” The South Korean companies LG Chem, SK Innovation and Samsung SDI are among the leading battery manufacturers and have a global market share of 30 percent.

Components of electric vehicles, which include batteries, must undergo certification in Korea. The KC mark or KC certificate is roughly equivalent to the European CE mark and applies to 730 different products, such as cars, elevators and many electronic products. MPR International GmbH – Korea Certification is represented by its own subsidiaries at five locations and thus completely covers the demand for certification services for the South Korean market. We offer certification services for all product areas. We have developed special expertise in the automotive, electrical, mechanical engineering, telecommunications and IT sectors. Our experts are always available to answer your questions without obligation.

If you need assistance or have any questions, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

LG Chem invests in battery joint venture with GM

The South Korean company LG Chem has started investing in a joint venture with GM for the production of battery cells for vehicles. Around 35 million US dollars flowed from LG Chem into the Ultium Cells joint venture in April 2020. In December 2019, LG Chem and GM had already announced that they would invest a total of the equivalent of 2.24 billion US dollars in the new company. According to LG, their share, which they will pay over the four years to 2023, is the equivalent of 831 million US dollars.

With the start of production at Ultium Cells, LG Chem will secure two production sites in the United States. The capacity of the plant in Holland in the US state of Michigan will be 5 GWh per year. According to the company, the total output of Ultium Cells will be 30 GWh per year. The company also plans to establish or expand other locations in Asia and Europe. Another joint venture is planned with the Chinese car manufacturer Geely. This site is to be completed by the end of 2021 and will have a capacity of 10 GWh. The existing plant in Wroclaw, Poland, will be expanded and its annual production capacity increased to 60 GWh.

Based on these plans, LG Chem’s production capacity for batteries for electric vehicles will grow to 200 GWh by 2023. This would mean that 3.3 million electric vehicles with a range of 380 kilometers could be charged once. Do you need Korea certification for automotive components?

MPR International GmbH has already successfully accompanied many large automotive suppliers and vehicle manufacturers in their certification projects for Asian markets and has been supporting many companies for several years. No matter if you are in the early stages of your planning or if you have already passed a certification and now new projects or follow-up audits are pending. When choosing MPR International GmbH you can rely on the greatest competence in the automotive sector.

If you need assistance or have any questions, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

German company receives license for LG’s vacuum cleaner robot

On June 1, the South Korean company LG Electronics announced that it had signed a licensing and patent utilization agreement with Miele, a German company leading the market for domestic appliances in Europe. The agreement allows Miele to produce and sell robot vacuum cleaners using LG Electronics’ patented technology. Previously, only the US company GE Appliance had such a license. The agreement with Miele includes three important patents held by LG Electronics for its vacuum cleaner robots.

These patents include automatic location of the charging station, sensors in the dust container filter and the coupling of the drive to the lower brush. LG Electronics has a total of more than 700 registered patents for vacuum cleaner robots. For another important product, refrigerators with an icemaker in the door, LG Electronics has already concluded an agreement with GE Appliance in June 2019. The patent is a key technology for the drinking water filters and ice-makers in the door of a refrigerator, which are widely used and popular in North America. In this area, LG Electronics has more than 400 registered patents worldwide for icemakers in refrigerator doors.

For import or sale in South Korea, household appliances are subject to KC certification (also called KC mark). The KC-Mark or KC certificate corresponds approximately to the European CE mark and applies to 730 different products. The main purpose of KC certification or Korea Certification is to identify and contain a potential risk to the health and safety of consumers. We would be pleased to advise you without obligation regarding Korea Certification and would be pleased to carry out this for you.

If you need assistance or have any questions, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

KT introduces new services for automated warehouses

South Korean telecommunications company Korea Telecom KT recently introduced its new automated warehouse services using a local 5G network and self-guided forklift trucks. The company uses this concept in its warehouse in Goyang, Gyeonggi Province.

The new system includes two different automated material handling vehicles that can transport large or heavy loads or follow an employee through the warehouse while assembling a shipment. The vehicle collects data in real time, which helps employees to optimize logistics processes. According to Korea Telecom, the automatic vehicles have reduced the distances walked by employees by 47 percent. The company also plans to extend the technology to other industries or applications in the areas of production, warehousing and material handling.

A spokesman for KT said they will work to further develop this novel logistics concept, as an increase in logistics and supply chains is expected after the end of the coronavirus epidemic. After testing it in a warehouse, the company plans to offer its services to other industries such as hospitals or libraries.

Most information, communication and telecommunications technology equipment sold in South Korea requires KC certification as well as KC EMC certification. For products with radio technology (RF), KC EMC certification is also required to gain access to the South Korean market. This affects products with radio technologies such as Wi-Fi, Bluetooth, RFID or other wireless communication technologies. MPR International GmbH has solid experience in Korea certification and competent local partners. We would be pleased to advise you without obligation about the scope and procedure of a Korea certification.

If you need assistance or have any questions, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Rising demand lifts mood among Korea’s semiconductor manufacturers

South Korea’s semiconductor industry is looking forward to the third quarter of this year despite the coronavirus crisis and difficult economic environment. According to information from industry representatives, demand is expected to rise, especially for memory chips used in the growing market for contactless electronic devices. Exports of semiconductors from South Korea increased by 22.6 percent in the first ten days of June 2020 compared to the previous year. This is supported by data from Korean customs.

Figures from the Korean Ministry of Industry, Trade and Energy show that in May semiconductor exports rose 6.6 percent, including both memory and non-memory chips. Exports of computer memory (DRAM) increased 17 percent year-on-year. An increase in DRAM prices contributed to the higher value of South Korea’s chip exports. The fixed price for a DDR4 8 GB memory module rose 0.6 percent to $3.31 in May. According to DRAMeXchange market observers, the price has been rising steadily over the past five months.

These confident figures suggest that Korean semiconductor manufacturers Samsung Electronics and SK hynix could report rising profits in the second quarter of 2020 after a negative first quarter result. Analysts expect that the chip industry could largely recover in the second half of the year and return to the level of six months ago. Sales of PCs and mobile devices will also increase in the third quarter as manufacturers try to make up for weak sales in the first six months with special offers and discounts. Another product for which experts predict an upturn is flash memory (NAND). Due to scarce production with higher market demand, the price could rise by about 9 percent, according to a report by NH Investment & Securities.

South Korea is considered one of the most important and innovative industrial nations in the world. To gain market access to this highly technological country, many products imported into South Korea must be tested and certified. The KC-Mark or KC certificate corresponds approximately to the European CE mark and applies to 730 different products, including many electronic products. Since 2005, MPR International has been supporting companies worldwide in the certification of products for the markets of Korea, China, Taiwan and India. MPR International offers you a complete package for certification in which you are excellently supported. We are available to you at any time for questions without obligation.

If you need assistance or have any questions, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Tesla leading in electric vehicle sales in South Korea

Tesla is boosting sales of electric vehicles in South Korea and making them more attractive to the general public. Previously, the car manufacturer had difficulties entering the Korean market. Potential buyers of Tesla vehicles were not entitled to the government’s generous bonuses of up to $21,000 for the purchase of electric cars. The reason was a regulation that vehicles eligible for the subsidy must be fully charged within 10 hours at a conventional power outlet.

This gives advantages to vehicles with smaller batteries and a shorter range. Models with larger batteries and range, such as Tesla’s, can be fully charged within 10 hours but require a special charging station with a high-voltage connection. The Korean government recognized this shortcoming and changed the regulation in July 2017, but Tesla’s S and X models remained too expensive. Only last year, when Tesla offered the Model 3 in South Korea, sales figures increased. Deducting the state premiums, the vehicle costs only $26,000. The launch of Tesla’s best-selling model has also significantly increased the acceptance and popularity of electric cars in South Korea.

For the first quarter of 2020, Korean automobile associations reported a 40 percent increase in sales of electric vehicles. Tesla sales rose to 4,075 vehicles from 236 last year, following the introduction of the affordable Model 3 in November. Korean manufacturers delivered 10,161 vehicles in the same period. However, this figure includes light commercial vehicles such as the Hyundai Porter II Electric, which was the most sold. In contrast, Tesla is the market leader for passenger vehicles. Other foreign manufacturers have only a small market share in electric cars. BMW delivered only 53 vehicles, Mercedes-Benz 23 and Jaguar 14. MPR International GmbH will be happy to advise you on Korean certification for automotive components. We have already successfully assisted many large automotive suppliers and also vehicle manufacturers with locations in Korea in their certification projects and have been supporting these companies for several years. Our experts are available to you at any time by phone or e-mail for questions regarding an upcoming Korea certification.

South Korea is considered one of the most important and innovative industrial nations in the world. To gain market access to this highly technological country, many products imported into South Korea must be tested and certified. The KC-Mark or KC certificate corresponds approximately to the European CE mark and applies to 730 different products, including many electronic products. Since 2005, MPR International has been supporting companies worldwide in the certification of products for the markets of Korea, China, Taiwan and India. MPR International offers you a complete package for certification in which you are excellently supported. We are available to you at any time for questions without obligation.

If you need assistance or have any questions, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Electronics industry prepares for growing demand

The South Korean electronics industry is preparing for increasing demand after an improvement of the coronavirus situation. Managers from the industry expect an increase starting from the second half of 2020. Experts from the semiconductor, display, telecommunications and battery industries met recently at an event organized by the Korean Chamber of Commerce to prepare for the market situation after the coronavirus. The participants agreed that the industry can only benefit from the new opportunities and sales markets if they are well prepared.

Industry experts expect a change in production towards content, services and new technologies based on video conferencing and remote maintenance without physical contact. As a result, demand for semiconductors and displays will increase dramatically in the second half of 2020. “In a scenario where the spread of the virus in the US and Europe is declining, there will be no negative impact on the semiconductor industry,” said Song Myung-seob, an analyst at Hi Investment & Securities. He also predicted an increase in demand for IT equipment, from which the semiconductor industry can benefit and recover from the setbacks.

Production of LCD displays in China will also return to normal in the second half of the year and eliminate the current bottlenecks, according to analysts. Demand is also expected to rise for lithium batteries and electronic devices from the healthcare sector for use at home. Despite the restrictions imposed by Covid-19, the market for electric vehicles is growing and Korean manufacturers should catch up with their Chinese competitors, said Kim Ji-san, an analyst at Kiwoom Securities. He predicts that the robotics market will also grow in addition to health and hygiene-oriented electronic devices.

South Korea is considered one of the most important and innovative industrial nations in the world. To gain market access to this highly technological country, many products imported into South Korea must be tested and certified. The KC-Mark or KC certificate corresponds approximately to the European CE mark and applies to 730 different products, including many electronic products. Since 2005, MPR International has been supporting companies worldwide in the certification of products for the markets of Korea, China, Taiwan and India. MPR International offers you a complete package for certification in which you are excellently supported. We are available to you at any time for questions without obligation.

If you need assistance or have any questions, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

South Korea’s industry makes headway in electric vehicle batteries

The leading battery manufacturers in South Korea – LG Chem, Samsung SDI and SK Innovation – were able to demonstrate solid success in recent months against the market power of China and technology leader Japan. In the first quarter of 2020, LG Chem, for example, was able to secure market leadership with 27.1 percent despite the difficult circumstances caused by the coronavirus. Nevertheless, experts and industry representatives warn that South Korea’s industry could suffer setbacks relatively quickly if it cannot keep up with the development of the next generation of automotive batteries.

An important factor is the development of solid-state or dry batteries. These use solid materials as energy storage, unlike liquid or polymer gel batteries such as lithium-ion batteries. Dry batteries may be safer and also offer a higher energy density which means they can store the same amount of energy but are smaller and lighter. Japan’s Fuji Economic Institute predicts that the market for solid state batteries will grow to $22.8 billion by 2035. Japan is currently the leader in solid state battery technology and companies in the US, China and Europe are working hard to catch up.

At a meeting of the boards of directors of Samsung and Hyundai Motors in May of this year, the further course of action regarding research and development of dry batteries was discussed. South Korea currently lags behind Japan, which plans to start serial production of dry batteries in 2022, while South Korean manufacturers have no prototypes yet. Toyota already announced in 2017 the introduction of electric vehicle solid batteries for 2020, the series production is planned for 2022. For this purpose, Toyota has signed a research and development agreement with Panasonic and in April 2020 founded the joint venture Prime Planet Energy & Solutions.

South Korea’s largest battery manufacturer LG Chem, on the other hand, doubts the economic viability of solid state batteries and is sticking with conventional lithium-ion batteries. In the meantime, Hyundai, a manufacturer of electric vehicles, has announced that it may develop its own solid state batteries. In this context, Hyundai Motor has already invested 5 million US dollars in the American company Ionic Materials in May 2018. Three months later, Hyundai Motor made a further investment in Solid Power, another US company in the field of solid state batteries. MPR International GmbH – Korea Certification is represented by its own companies at five locations in South Korea and thus completely covers the demand for certification services for the South Korean market. Our experts are available at any time and without obligation to answer your questions regarding a new upcoming certification or a follow-up audit.

If you need assistance or have any questions, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Simplified approval process for chemicals to ensure better supply

On 20 May 2020, the Korean Ministry of Environment reported that the simplified approval processes such as registration, evaluation and control of chemicals have led to a 61 percent increase in supply. In particular, the supply of special or difficult-to-obtain substances has improved. According to the ministry, the simplified approval process was applied to 15 types and 37 individual cases at a total of 32 companies.

The period for granting or amending an operating license of the above-mentioned companies was reduced from 75 to an average of 30 days. As a result, the supply of perishable chemicals such as hydrofluoric acid was increased from 105,000 to 166,000 tons. Accordingly, the registration of such substances was accelerated and the daily available quantity for the domestic chemical industry increased from 1,900 to 122,000 tons.

The simplified regulations were introduced in order to continue to provide companies in the semiconductor and battery manufacturing industries with the necessary raw materials and to avoid production interruptions. In recent months, the global outbreak of Covid-19 and a resulting export ban by Japan has led to shortages of chemicals in Korean industry.

We would be pleased to support you with your Korea certification and are also available to answer your questions at any time. Send us an email or call us at +49-69-2713769259.